CUTTING-EDGE CHILLERS FOCUSED ON ENERGY SAVINGS

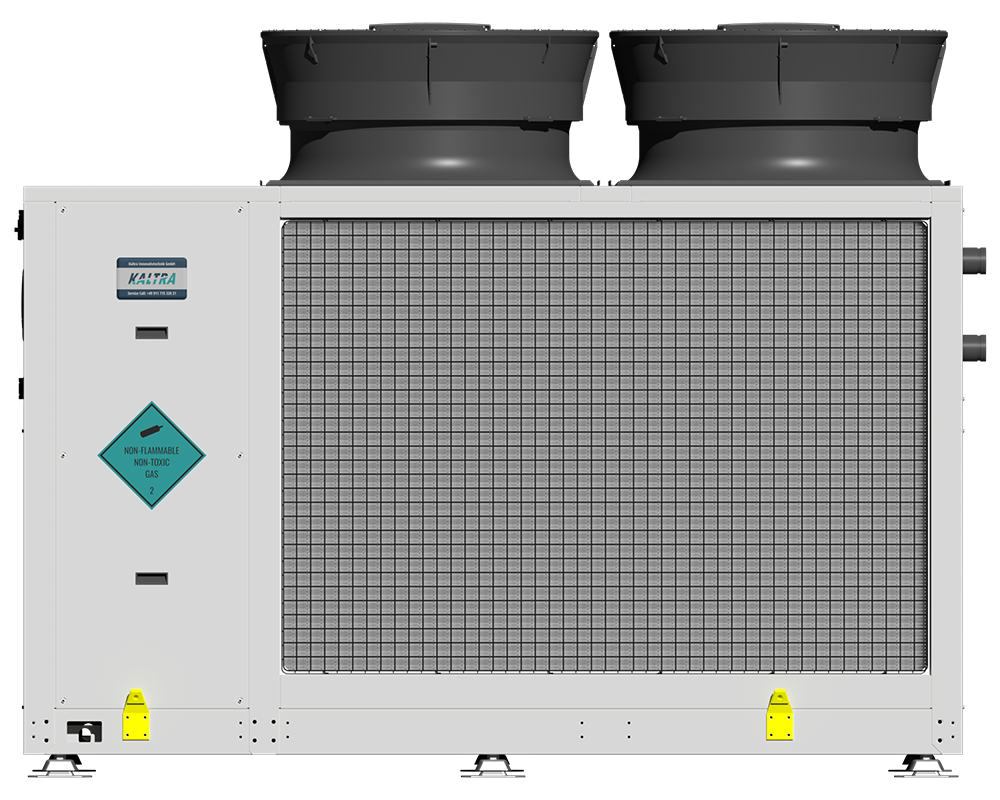

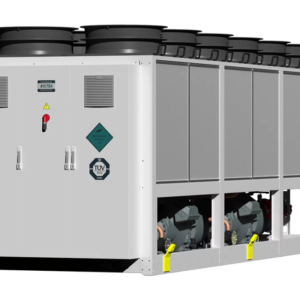

Ultracompact II chiller family provides capacity-matched cooling, precise outlet water temperatures and water flow. These chillers display improved performance, compact footprint, and deliver the highest efficiency rates based on key innovations and enhancements in their design. The built-in reliability of Ultracompact II makes this machine a top league player in the field of process cooling, air conditioning, and refrigeration applications.

The range includes air-cooled models and models with evaporative pre-cooling, based on multiple scroll compressor technology and microchannel condensers, with advanced evaporation control and optimized control software.

The improved full- and part-load efficiency of the Ultracompact II series enables customers to engineer chilled water production plants which meet the highest international energy-efficiency standards.

10%

ENERGY SAVINGS

Ambient air temperature/humidity: 35ºC/50%rH

Water temperatures: 7/12ºC

ULTRACOMPACT II STANDARD

AIR-COOLED CHILLERS

Ultracompact II is the latest and most energy-efficient family of air-cooled chillers with latest generation scroll compressors running on refrigerant R410a.

Undertaking close approach evaporators, improved microchannel condensers, large-diameter EC-driven fans, precise expansion valves, optimized control software – contribute to the high energy efficiency of Ultracompact II.

- High energy efficiency (EER) – up to 3.29

- Compact and lightweight

- Intelligent head pressure control

- Extended supply water temperature range – up to -12ºC

- Optional heat recovery

37%

ENERGY SAVINGS

Ambient air temperature/humidity: 35ºC/50%rH

Water temperatures: 7/12ºC

ULTRACOMPACT II E•VAP

EVAPORATIVE CHILLERS

The working principle underlying an Ultracompact II evaporative chiller is the pre-cooling of ambient air before it enters the chiller’s condensing coils.

Evaporative system engineered for Ultracompact II allows reducing ambient air temperature to close to wet-bulb temperature – thank its innovative design and materials used for evaporative media – and offers valuable advantages for Ultracompact II customers:

- High energy savings on compressors – up to 35%

- Reduced compressor peak loads

- Increased cooling capacity – up to 10%

- Extended operating limits, e.g., working conditions of up to +55ºC

- Lower noise emissions

SCROLL COMPRESSORS

PROVEN PERFORMANCE AND RELIABILITY

The combination of an energy-efficient motor and an optimized scroll wrap for refrigeration applications provides a high degree of efficiency in Ultracompact II’s compressors. Reliability is built into this compressor range, from the compliant scroll design and the engineered bearings to the simplified design. The thermal fault protection also contributes to excellent reliability.

As a predominant operating mode of typical Ultracompact II applications is part-load, particular importance was placed on low energy consumption at low saturation discharge temperatures.

Customers of Ultracompact II chillers with multiple scroll compressor technology can benefit from time-proven reliability, low sound levels, low vibration, and minor operating and maintenance costs.

EVAPORATORS

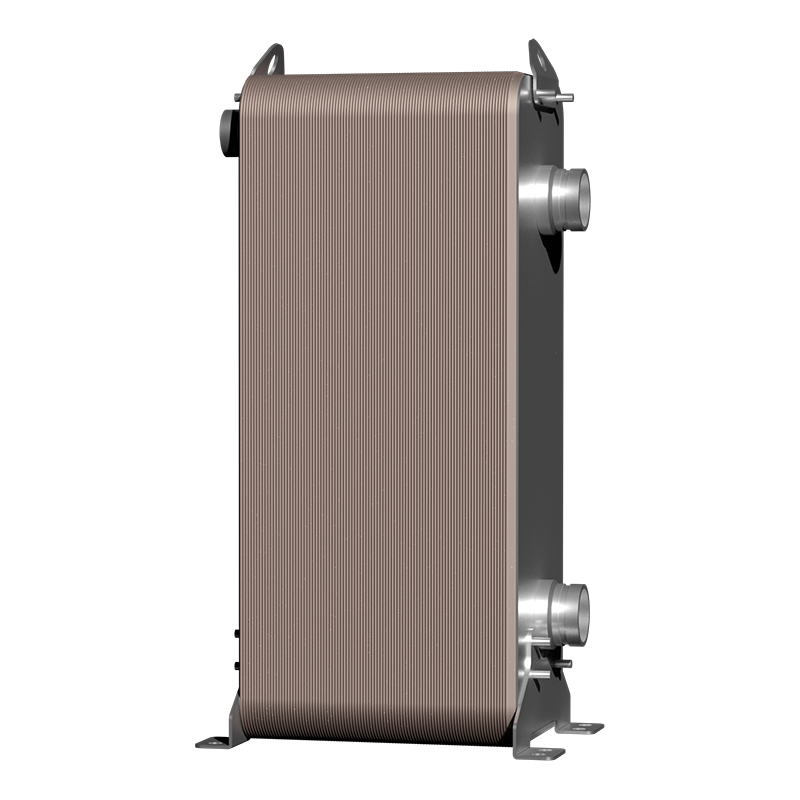

BRAZED PLATE HEAT EXCHANGERS

As the evaporator approach temperature difference becomes small, the performance of the system improves, and therefore the operating cost is reduced. To keep the minimal approach temperature, we adopted the most efficient plate evaporators available today and lifted the compressor COP to save as much energy as possible.

Brazing the stainless steel plates together eliminate the need for gaskets and thick frame plates, which makes the heat exchanger compact. The special plate design guarantees a consistent braze joint at the plate overlap and makes for stronger and more leak-proof heat exchanger. The brazing material seals and holds the plates together at the contact points, ensuring optimal heat transfer efficiency and pressure resistance. Using advanced design technologies and extensive verification guarantees the highest performance and longest possible service lifetime.

Evaporation Control

Accurate control of superheat with the Ultracompact II scroll chiller operating at part load achieved with electronic expansion valves. Fitting EEV permits a reduction in power consumption of up to 30% by controlling the refrigerant flow at reduced head pressures.

The EEV used in Ultracompact II chillers are new generation valves designed for precise liquid injection in an evaporator and includes balanced cage and slider assembly operated by direct driven motor technology. This ensures solenoid-tight shut-off in both flow directions, thus providing smooth operation of the system. The valve incorporates a powerful bi-polar motor which precisely controls flow regulation.

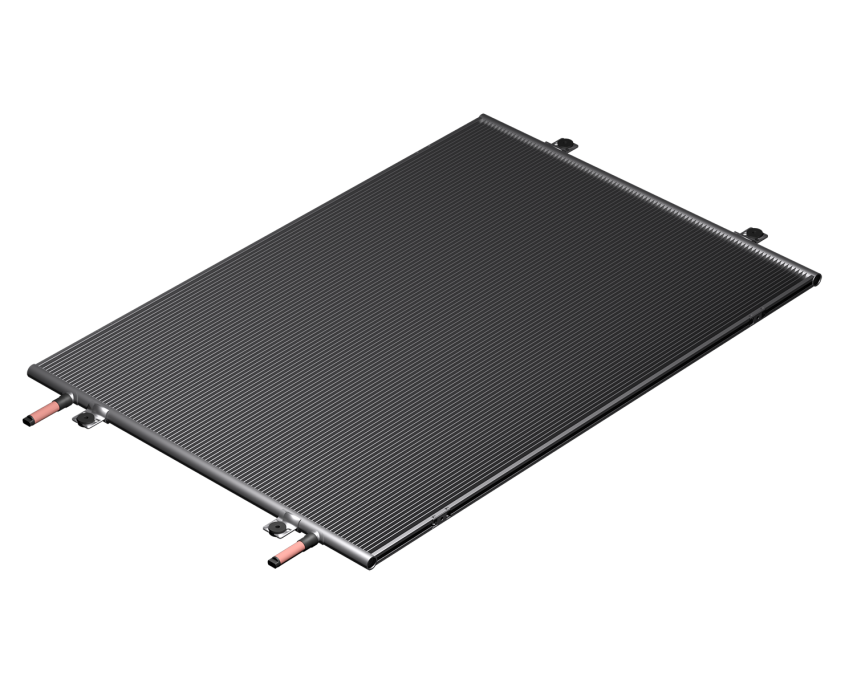

MICROCHANNEL CONDENSERS

All-aluminium microchannel condensing coils used in Ultracompact II chiller range allows achieving the number of advantages that improve energy efficiency:

- Higher heat transfer rates

- Lower airside pressure drops and consequentially reduced fan energy

- Lower condensing temperatures

The end result is up to 40% higher energy efficiency of the chillers in comparison to those featuring finned tube coils. Furthermore, lower condenser weight and reduced refrigerant charge translate to lower unit’s cost. Based on the all-aluminium construction, microchannel condensing coils are also subject to significantly less galvanic corrosion than traditional finned tube designs, in that there are no dissimilar metals.

POWER-SAVING FANS

OPTIMIZED AIRFLOW AND MAXIMUM EFFICIENCY

Axial fans used in Ultracompact II design have outstanding characteristics in every respect, including performance and efficiency, weight, noise pollutions, and robustness.

EC fan technology is an excellent solution for demand-responsive cooling, and we equip Ultracompact II chillers with the latest EC motors which demonstrate impressive performance, low energy consumption, high torque, and durable design. EC fans with integrated electronic control can easily be varied in speed to match airflow demand. For the same air volume, they consume distinctly less energy than AC motors.

The most common cause of fan motor failure and consequent capacity reduction of the chiller is overheating. EC fans of Ultracompact II chiller have temperature sensors built into the internal electronics package that act as a safety device in the event of overheating.

Compared to AC motors, EC-type motors have a longer service life due to lower winding temperatures resulting in lower wear and tear. Comprehensive corrosion protection measures have been taken to allow the fans to be used in almost all climatic applications with outstanding operating reliability.

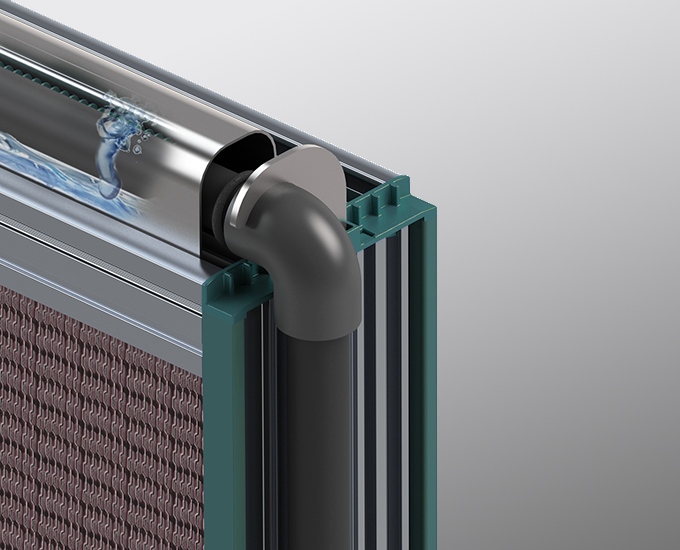

Evaporative Pre-Cooling

BOOSTS SYSTEM EFFICIENCY UP TO 35%

REDUCES COMPRESSOR WORK

Evaporative pre-cooling system permits the reduction in the temperature of air delivered to condensers even in hot and humid environments and expands the scope of operation of Ultracompact II chillers up to +55°C while maintaining the same level of efficiency. Equipping Ultracompact II chillers with evaporative pads results in significant electricity savings of up to 35%.

The evaporative media of E•VAP™ is based on water-retaining finned aluminium plates designed for maximum evaporation: saturation efficiency reaches 90% and higher at air velocities of up to 2m/s. The internal geometry and special fin coating of evaporative media facilitate cleanliness of the evaporative media during operation.

In order to achieve maximum efficiency and minimal water usage, E•VAP™ pre-cooling system can be equipped with a pumping station which includes the circulation pump, water treatment module, and control system with sophisticated algorithms that monitor the ambient conditions and determine the optimum operation modes, ensuring the E•VAP™ system is active only when necessary. The fully automated water management system continuously monitors water quality, drains the system and refreshes the water when mineral levels reach certain values.

Evaporative pads can be easily detached for maintenance and access to the chiller’s condensing coils for cleaning.

OPTIONAL EXTRAS

A vast selection of miscellaneous options and accessories are available for Ultracompact II, making it suitable for all applications in air conditioning, industrial process cooling, and refrigeration:

PRODUCT SPECIFICATIONS

| Capacity [kW] | 50 … 300 |

|---|---|

| Design | AIR-COOLED/EVAPORATIVE |

| Compressors | SCROLL |

| Refrigerant | R410A/R32/R452b/R454b |

| Energy efficiency (EER) | UP TO 3.29 |

| Seasonal efficiency (ESEER) | UP TO 4.68 |

| Fan motors | EC |

| Condensers | MCHE |

| Evaporators | BPHE |

| Evaporation control | EEV |

| Refrigeration circuits | SINGLE/MULTIPLE |

| Warranty | 3 YEARS |