VERSATILE SOLUTION FOR CHILLED WATER PRODUCTION

Ultracompact is a family of air-cooled chillers that offer best-in-class efficiency in a compact footprint and provide capacity-matched cooling, precise temperature control and water flow. Housed in a lightweight, aluminum enclosure, these chillers are easy to install and startup, require minimum maintenance and distinguish by a long service life.

An extensive set of optional components among which hydronic modules, water tanks, heat recovery system, low-noise configurations, and more makes Ultracompact chillers a versatile and flexible solution for air conditioning, industrial process cooling, and refrigeration applications.

SCROLL COMPRESSORS

RELIABLE SOLUTION FOR ENSURED CONTINUITY IN APPLICATIONS

The combination of an energy-efficient motor and an optimized scroll wrap for refrigeration applications delivers high efficiency in Ultracompact’s compressors. Reliability is built into this compressor range, from the compliant scroll design and the engineered bearings to the simplified design. Thermal fault protection also contributes to excellent reliability.

As a predominant operating mode of typical Ultracompact applications is part-load, particular importance was placed on low energy consumption at low saturation discharge temperatures.

Customers of Ultracompact chillers with multiple scroll compressor technology can benefit from time-proven reliability, low sound levels, low vibration, and minor operating and maintenance costs.

POWER-SAVING FANS

AXIAL FANS WITH REDUCED POWER CONSUMPTION

Ultracompact’s new intelligent fan system consisting of profiled, sickle-shaped axial fans, multifunctional air guide vanes, and optional diffusers – provides maximum flexibility, lowest sound emissions, and the highest degree of energy efficiency.

Standard configuration includes AC-motor fans, while the fans with electronically commutated (EC) motors that produce savings in both full-load and partial load operations are available as an option.

EVAPORATORS

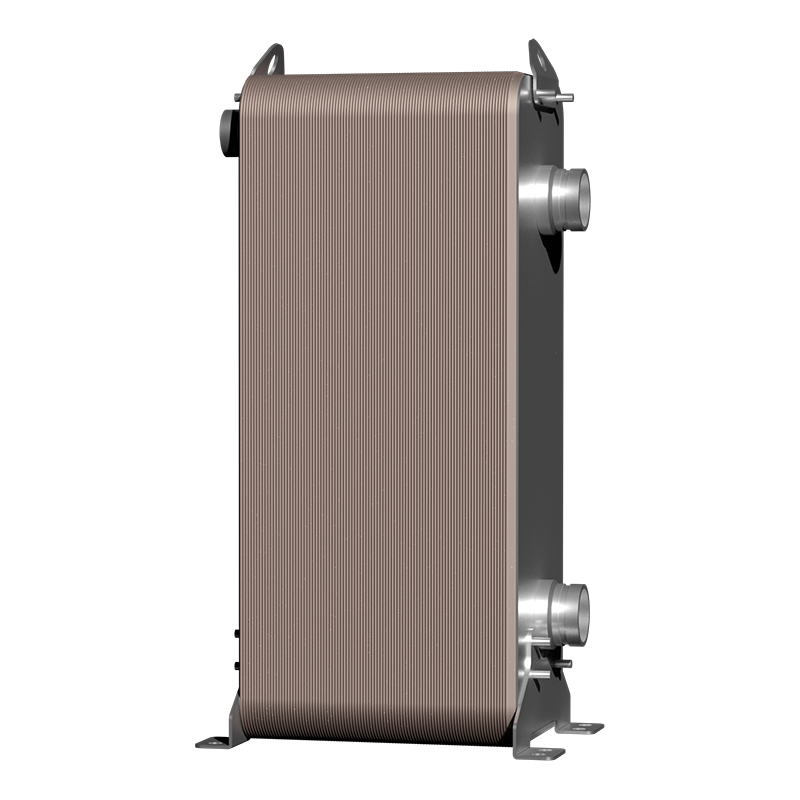

BRAZED PLATE HEAT EXCHANGERS

As the evaporator approach temperature difference becomes small, the performance of the system improves, and therefore the operating cost is reduced. To keep the minimal approach temperature, we adopted the most efficient plate evaporators available today and lifted the compressor COP to save as much energy as possible.

Brazing the stainless steel plates together eliminate the need for gaskets and thick frame plates, which makes the heat exchanger compact. The special plate design guarantees a consistent braze joint at the plate overlap and makes for stronger and more leak-proof heat exchanger. The brazing material seals and holds the plates together at the contact points, ensuring optimal heat transfer efficiency and pressure resistance. Using advanced design technologies and extensive verification guarantees the highest performance and longest possible service lifetime.

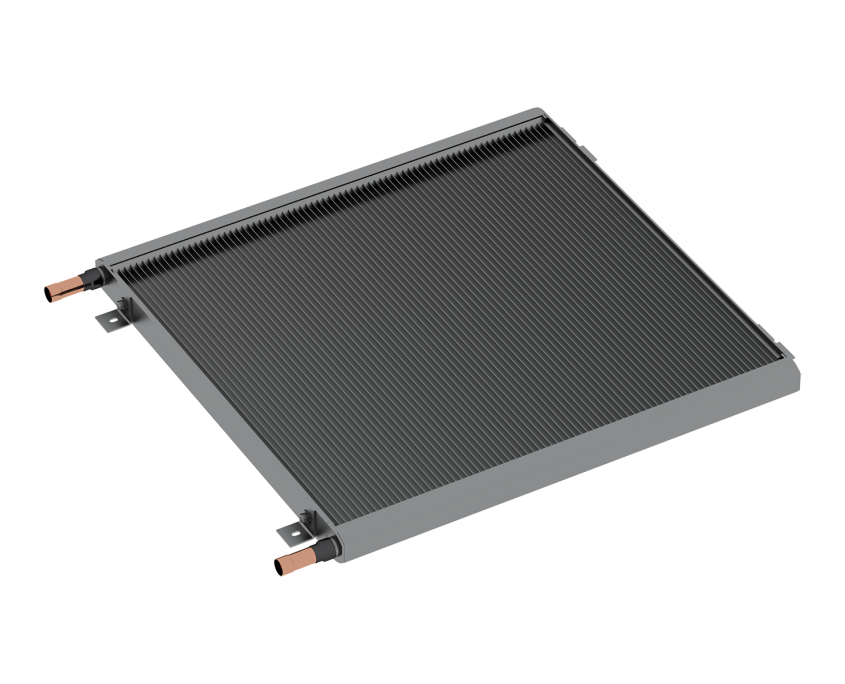

MICROCHANNEL CONDENSERS

All-aluminium microchannel condensing coils used in Ultracompact air-cooled chiller range allows achieving the number of advantages that improve energy efficiency:

- Higher heat transfer rates

- Lower airside pressure drops and consequentially reduced fan energy

- Lower condensing temperatures

The end result is up to 40% higher energy efficiency of the chillers in comparison to those featuring finned tube coils. Furthermore, lower condenser weight and reduced refrigerant charge translate to lower unit’s cost. Based on the all-aluminium construction, microchannel condensing coils are also subject to significantly less galvanic corrosion than traditional finned tube designs, in that there are no dissimilar metals.

OPTIONAL EXTRAS

PRODUCT SPECIFICATIONS

| Capacity [kW] | 50 … 300 |

|---|---|

| Design | AIR-COOLED |

| Compressors | SCROLL |

| Refrigerant | R410A |

| Energy efficiency (EER) | UP TO 2.98 |

| Seasonal efficiency (ESEER) | UP TO 4.22 |

| Fan motors | AC/EC |

| Condensers | MCHE |

| Evaporators | BPHE |

| Evaporation control | EEV |

| Refrigeration circuits | SINGLE/MULTIPLE |

| Warranty | 3 YEARS |