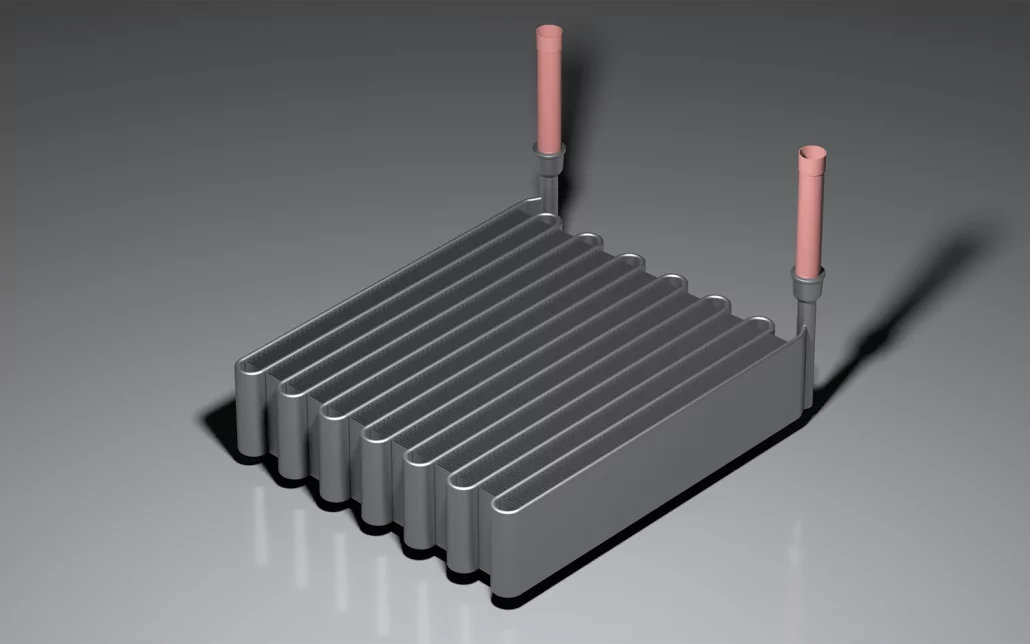

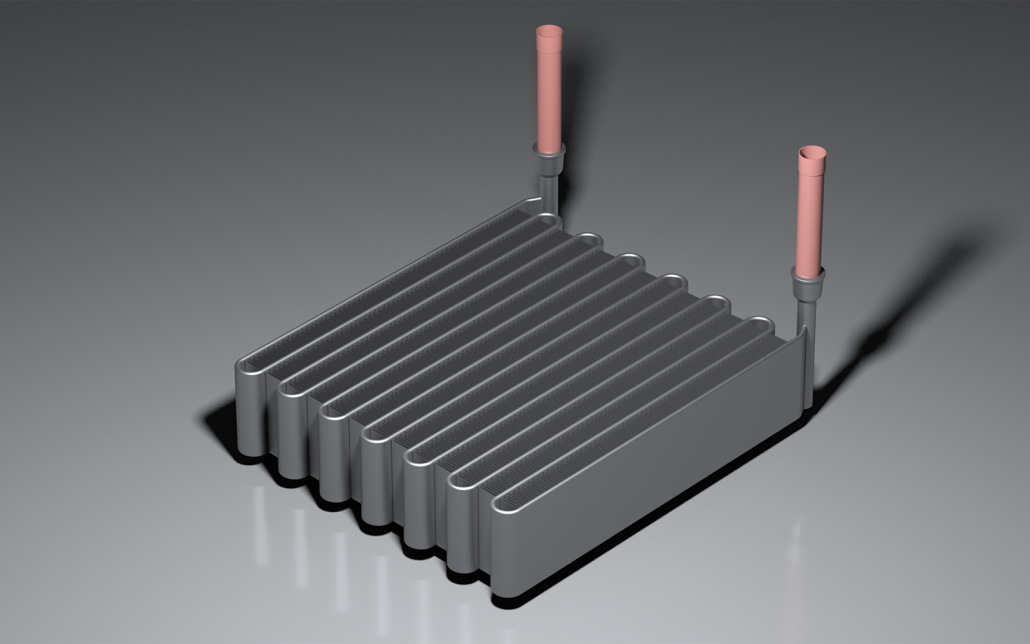

SERPENTINE CONDENSER / EVAPORATOR DESIGN

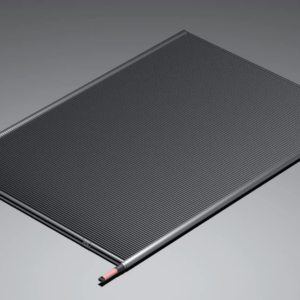

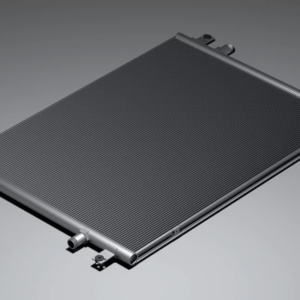

Serpentine heat exchanger typically consists of a single microchannel tube bent into a serpentine shape, fins, and connection pipes. All components are integrally brazed together in controlled atmosphere brazing (CAB) furnace:

- Microchannel tube bent into a serpentine shape

- Fin strips

- Inlet/outlet connections

Features and Advantages

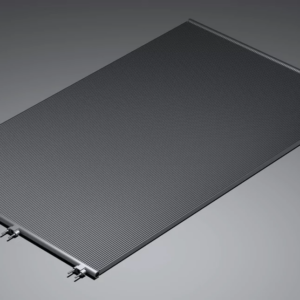

For 3kW of heat rejection or cooling, serpentine heat exchangers are the smallest and most versatile heat exchangers in the industry for refrigerant condensers, evaporators in compressorized and pumped loop refrigerant systems, and can be configured as evaporators for non-condensing cooling applications. Serpentine coils are designed to deliver maximum heat transfer, reliability, and easy packaging.

- Selection of aluminum alloys, including SLLA

- Refrigerant compatibility: HFCs/HFOs, natural gases

- Single- or multiple-circuit designs

- Designs with multiple coil cores

- Selection of flat our louvered fins

- Connections made from copper or aluminum

- Mountings made to order

- Protective coatings

Applications

Serpentine heat exchangers are perfectly suitable for any compact cooling or heat rejection solution as a condenser or evaporator coils, be it stationary systems or systems in constant motion. Using serpentine microchannel heat exchangers, some thermodynamically efficient but flammable refrigerants can be extended to more applications – thanks to the small internal volume of the coil and less refrigerant charge.

- Electronics cooling

- Medical applications

- Laser cooling

- Military applications

- Rack-mounted cooling systems

- Portable cooling solutions

- Beverage and ice-making applications

- Fractional horsepower equipment

PRODUCT SPECIFICATIONS

| Max width [mm] | 25 … 500 |

|---|---|

| Max height [mm] | 25 … 400 |

| Tube width [mm] | 12/16/20/25/32/36 |

| Manifold diameter [mm] | 16/20/25/30/32/38/42/50 |

| Fin types | FLAT/LOUVERED |

| Fin pitches [FPI] | 10/16/18/19/21/23/24/BY REQUEST |

| Design pressure [bar] | 32/45 |

| Refrigerants | HFC/HFO/NATURAL |

| Protective coatings | E-COATING/TCP-COATING/HYDROPHILIC |