ADVANTAGES

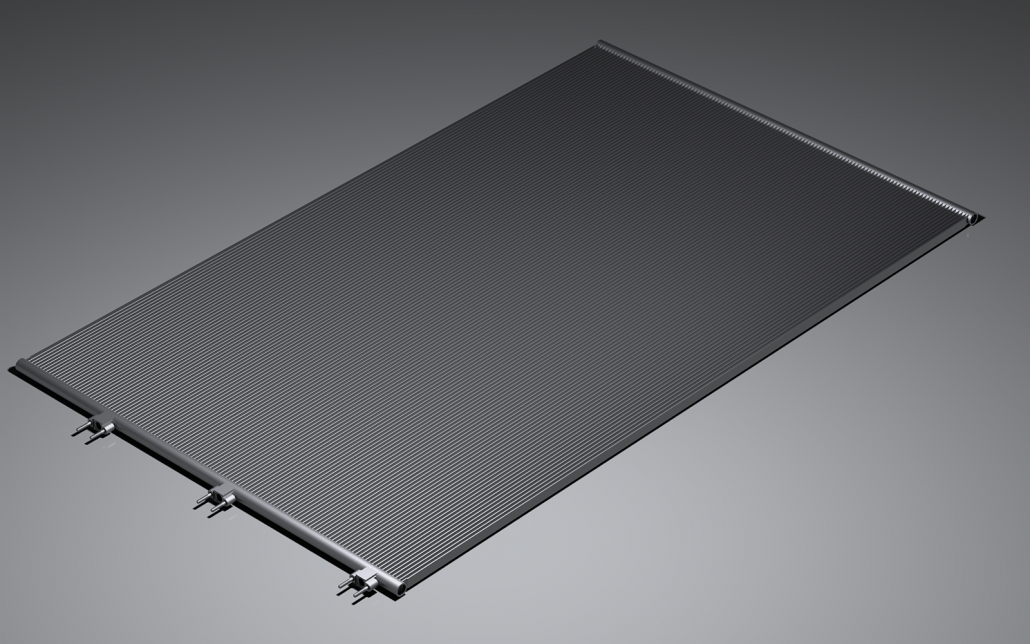

- Full compatibility, exact matching with original coils

- Long service life and extended warranty: 5 years for e-coated coils; 2 years for uncoated coils

- Protective coatings (e-coating or TCP-coating)

- Improved heat transfer performance

- Short lead times/stock availability

- Optional casings and mountings

- 100% factory tested, CE-marked, UL-listed

- Detailed installation guidelines

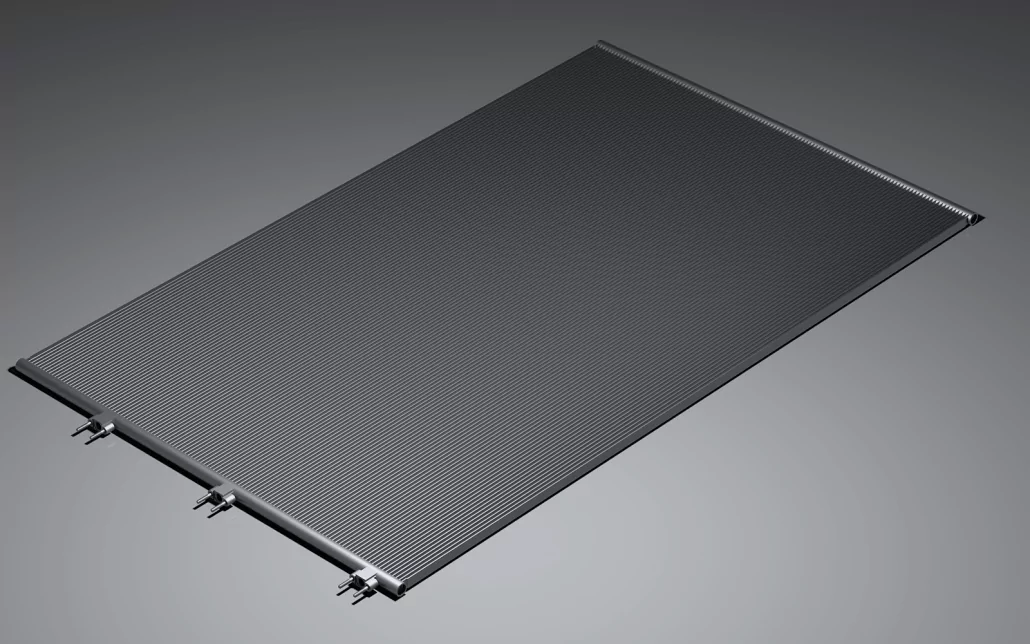

A full nomenclature of condenser coils for various chiller brands and models, with or without anti-corrosion treatments (e-coating), are available from stock.

Based on the model name or serial number of the chiller or leaked/damaged coil, you can easily select and order a replacement:

- York YVAA and York YLAA series microchannel condenser coils

- Trane RTAF and Trane CGAF series microchannel condenser coils

- Carrier 30RB, Carrier 30XA and Carrier 30XV microchannel condenser coils

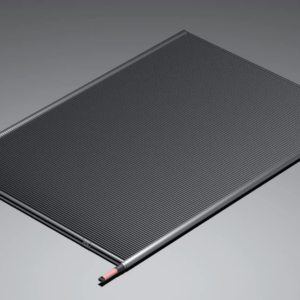

Coatings

Protective coatings significantly improve the corrosion resistance of microchannel heat exchangers and are recommended for installations in coastal and high-polluted zones, industrial and urban. Coatings also recommended for replacement coils where original coils displayed signs of oil spots, leaks, or traces of corrosion.

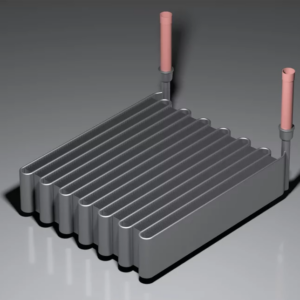

Options

Optionally, replacement coils can be made with modifications as per customer requirements, targeted to better heat exchanger efficiency and flexibility. Additional mountings, connections are available by request. Replacements for finned tube heat exchangers may include coil casings for matching dimensions of the original coil.