TOP EFFICIENCY AND 24/7 RELIABILITY

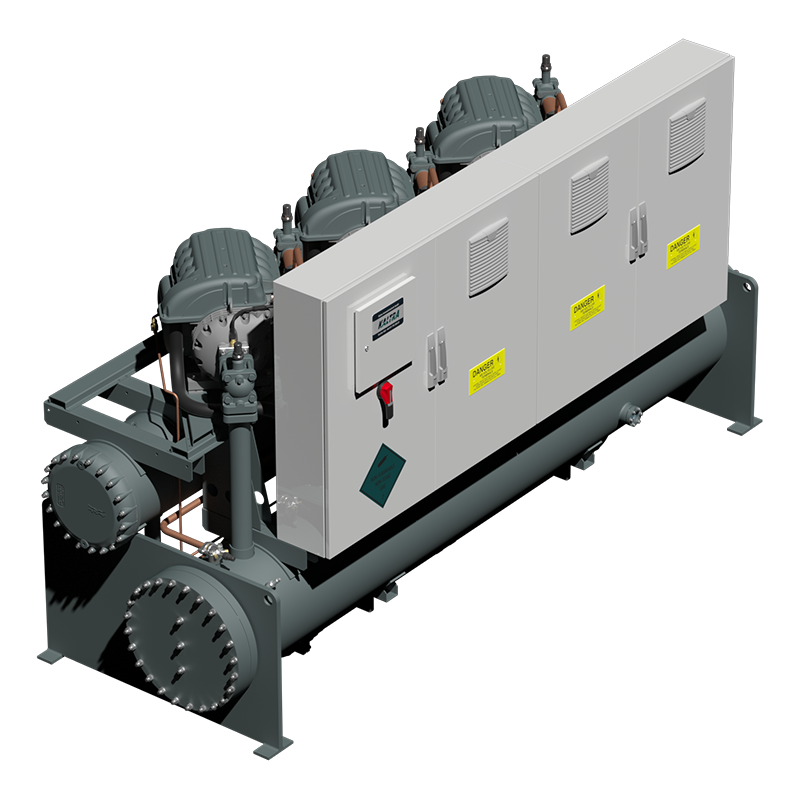

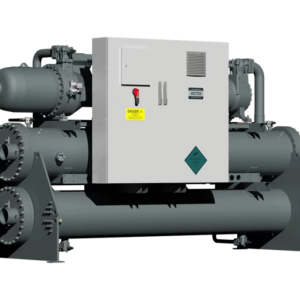

Powerstream Turbo combines ultra-efficient and quiet oil-free Turbocor compressors and the latest flooded condenser/evaporator technology to lift full- and part-load efficiencies. In addition to refrigerants R134a and R513a, these water-cooled chillers are available with R1234ze, a refrigerant with a low global warming potential.

A vast range of Powerstream Turbo models and options provides flexibility, tailor made to customer requirements permitting truly efficient cooling solutions for every application. Powerstream Turbo has been designed for all-year-round mission-critical service. In a 24/7 world, ensuring facilities stay up and running is critical, therefore special attention has been paid to control and monitor functionality, and ensuring operational reliability and ease of maintenance.

Due to its excellent efficiency under part-load conditions, Powerstream Turbo is an excellent economic solution for applications where the heat load is not constant or expected to increase. The synergy of modern technology, efficiency and reliability enable Powerstream Turbo to be used in the most demanding applications.

FEATURES AND ADVANTAGES

POWERSTREAM TURBO

Based on oil-free Turbocor compressors, Powerstream Turbo offers stand-out advantages for the customers in terms of energy savings, performance, and environmental safety.

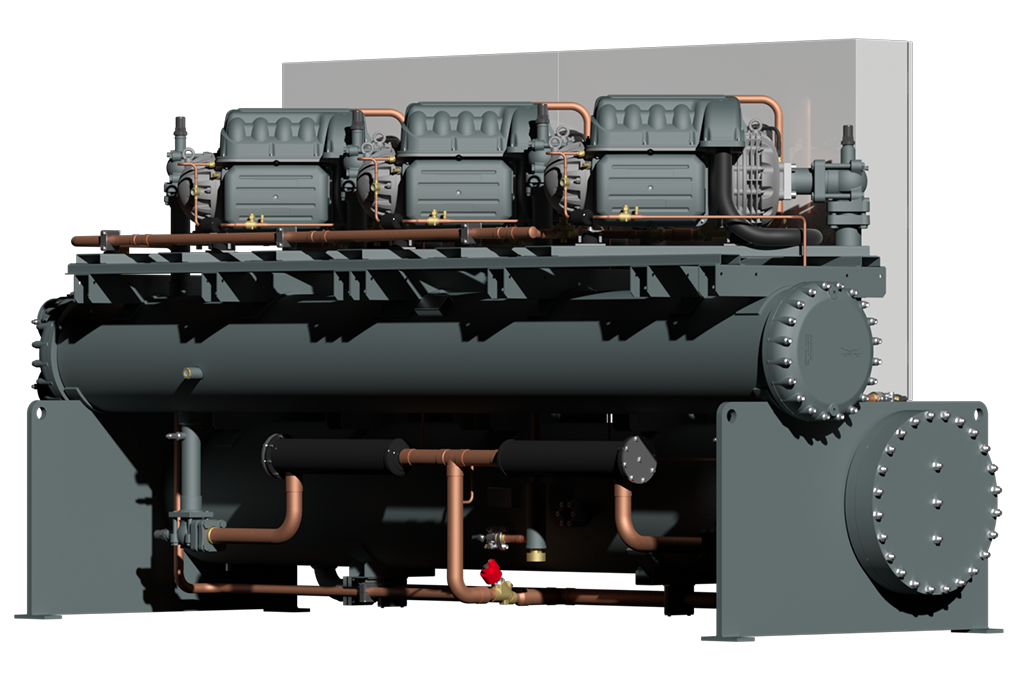

Under the control of advanced software developed especially for multi-compressor Turbocor chillers and with design improvements like flooded evaporator technology and advanced evaporation control, Powerstream Turbo is a top performer in providing efficient and reliable cooling.

- Exceptionally high seasonal energy efficiency (ESEER) of up to 10.50

- Efficiency and thermal stability at full- and part-loads

- Proven 24/7 reliability

- Environmental safety using refrigerant R1234ze

- Economizers to boost output and efficiency

DESIGN AND COMPONENTS

Powerstream Turbo chillers are assembled from premium quality, high-performance components, making it the most reliable choice for every application, be it high-availability data center, process cooling, or air conditioning.

- Turbocor compressors

- Flooded evaporator

- Water-cooled condenser

- Economizer

- Advanced controls

Compressor Management System

Powerstream Turbo’s advanced control software ensures the optimum efficiency across the whole operating range of the chiller and guarantees the chiller to work within the safe limits.

To achieve the best possible efficiency for multi-compressor chillers, compressor management software constantly monitors the actual cooling demand and selects the most efficient combination of the compressors to match. The software regulates optimum rotation speed and compression ratio, positions the inlet guide vanes and controls bypass valves.

GREEN R1234ZE SOLUTION

ENVIRONMENT-FRIENDLY REFRIGERANT

The proposed phase-down of HFC refrigerants has prompted an assessment of alternative fluids for a wide range of applications, including medium-temperature water-cooled chillers.

Recently developed R1234ze refrigerant features low global warming potential and zero ozone depletion potential and meets EU regulatory requirements for reducing the use of high global warming potential (GWP) substances. At the same time, R1234ze almost exactly matches the efficiency of R134a.

With R1234ze, Powerstream Turbo provides the environmental leadership while achieving the best energy performance levels for applications.

DRY COOLER SELECTION

We recommend operating Powerstream chillers together with Bora or Mistral series dry coolers. These dry coolers specifically engineered and optimized for use with water-cooled chillers, offer high performance, and enable a close temperature approach.

Bora Series

The Bora series is well-suited for urban locations due to their low sound emission, as well as for high-polluted areas and coastal installation due to the high corrosion resistance of microchannel heat exchangers used in the unit design. For the installations in hot climate zones, we recommend Bora dry coolers with evaporative pads. Evaporative dry coolers lower temperature of the air entering cooling coils, thus enabling lower condenser water temperatures and providing energy savings on compressors of up to 35%. Bora dry coolers feature EC-fans with Modbus control and supplied pre-wired.

Mistral Series

Mistral series dry coolers equipped with finned tube heat exchangers with internally grooved copper tubes and are ideal for any kind of industrial and commercial applications. These dry coolers are inherently robust, simple by design and perfect in the specification. Protective coatings make Mistral dry coolers highly corrosion-resistant and improve service life of the system.

PRODUCT SPECIFICATIONS

| Capacity [kW] | 300 … 4600 |

|---|---|

| Design | WATER-COOLED |

| Compressors | TURBOCOR |

| Refrigerant | R134A/R513A/R1234ZE |

| Energy efficiency (EER) | UP TO 6.40 |

| Seasonal efficiency (ESEER) | UP TO 10.50 |

| Condensers | FLOODED S&T |

| Evaporators | FLOODED S&T |

| Evaporation control | EEV |

| Refrigeration circuits | SINGLE |

| Warranty | 3 YEARS |