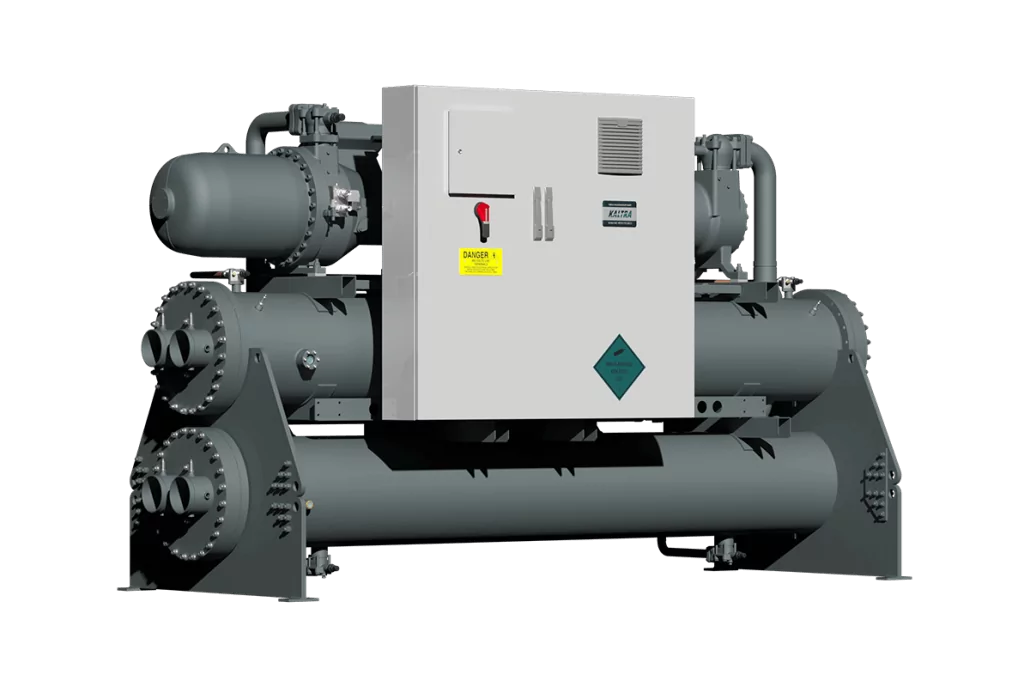

INDUSTRY-GRADE WATER-COOLED CHILLERS

This range features all the distinctive characteristics that place Powerstream Screw chillers at the top of their class: highly reliable compressors, stepless capacity control, versatile control software, and extended operating range to cover different application scenarios.

The chillers are intended for 24/7 use during their entire lifespan in industrial environments, easy in installation and startup, and require minor maintenance. Users can select from dozens of models to exactly match existing cooling loads and to fulfill today’s stringent environmental policies: besides R134a-driven versions, we offer models running on reduced-GWP refrigerants R513a and R450a.

FEATURES AND ADVANTAGES

POWERSTREAM SCREW

Of the lengthy list of advantages of Powerstream Screw chillers, the most significant are reliability and long service life. Other benefits include:

- Premium efficiency at partial and full loads

- Selection of refrigerants, including lower GWP mixtures

- Low pressure drops on flooded evaporator and water-cooled condenser, enabling energy savings on pumping

- Low installation and maintenance costs

- Reduced operating costs

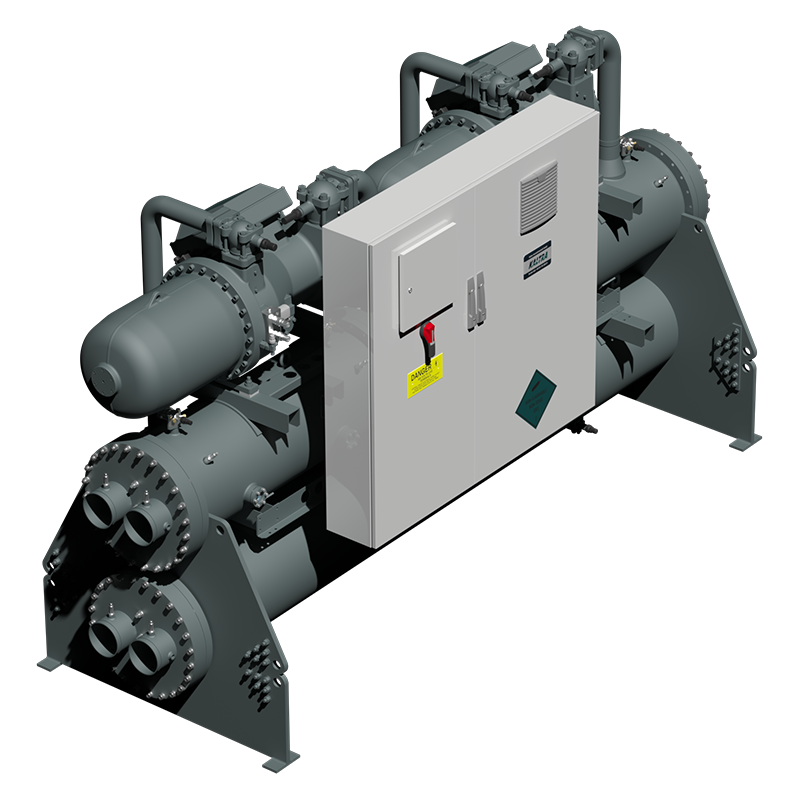

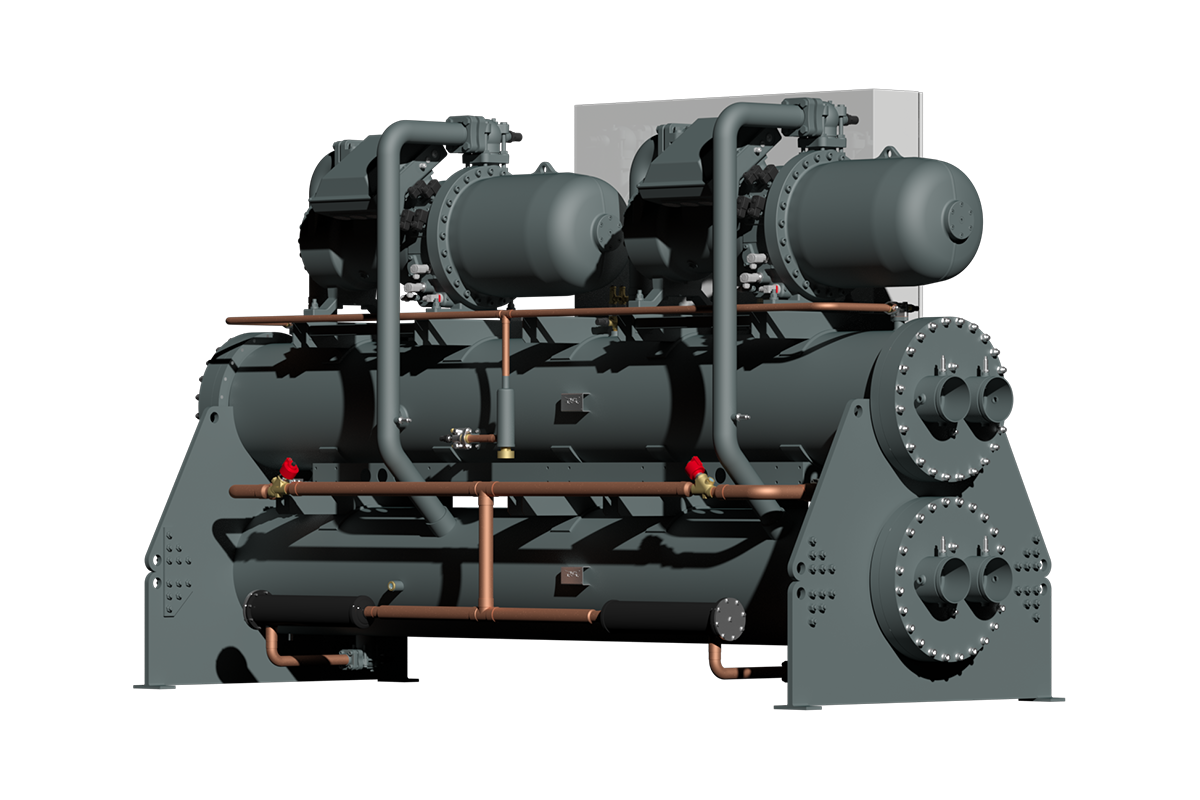

DESIGN AND COMPONENTS

Simple and time-proven design of Powerstream Screw chillers includes the latest components and technology in refrigeration, thus guaranteeing optimized performance and reduced energy use in applications.

- Semi-hermetic screw compressors

- Control software

- Flooded evaporator

- Shell-and-tube condenser

DRY COOLER SELECTION

We recommend operating Powerstream chillers together with Bora or Mistral series dry coolers. These dry coolers specifically engineered and optimized for use with water-cooled chillers, offer high performance, and enable a close temperature approach.

Bora Series

The Bora series is well-suited for urban locations due to their low sound emission, as well as for high-polluted areas and coastal installation due to the high corrosion resistance of microchannel heat exchangers used in the unit design. For the installations in hot climate zones, we recommend Bora dry coolers with evaporative pads. Evaporative dry coolers lower temperature of the air entering cooling coils, thus enabling lower condenser water temperatures and providing energy savings on compressors of up to 35%. Bora dry coolers feature EC-fans with Modbus control and supplied pre-wired.

Mistral Series

Mistral series dry coolers equipped with finned tube heat exchangers with internally grooved copper tubes and are ideal for any kind of industrial and commercial applications. These dry coolers are inherently robust, simple by design and perfect in the specification. Protective coatings make Mistral dry coolers highly corrosion-resistant and improve service life of the system.

PRODUCT SPECIFICATIONS

| Capacity [kW] | 250 … 1700 |

|---|---|

| Design | WATER-COOLED |

| Compressors | SCREW |

| Refrigerant | R134A/R513A/R450A |

| Energy efficiency (EER) | UP TO 5.82 |

| Seasonal efficiency (ESEER) | UP TO 7.68 |

| Condensers | S&T |

| Evaporators | FLOODED S&T |

| Evaporation control | EEV |

| Refrigeration circuits | SINGLE/DUAL |

| Warranty | 3 YEARS |