RELIABLE AND COST-EFFICIENT HEAT REJECTION SOLUTION

This comprehensive range of dry coolers, which includes more than 600 models in a horizontal design and 850 models in a V-shaped design, with a capacity range from 10 to 2000 kilowatts, has been engineered for maximum efficiency and flexibility. The machines offer easy installation, low maintenance costs, and long service life.

Mistral dry coolers characterized by low sound emission fans, enhanced finned tube heat exchangers with an increased tube wall thickness and thicker fins, and a huge choice of options and accessories for tailor-made solutions.

ADVANTAGES AND BENEFITS

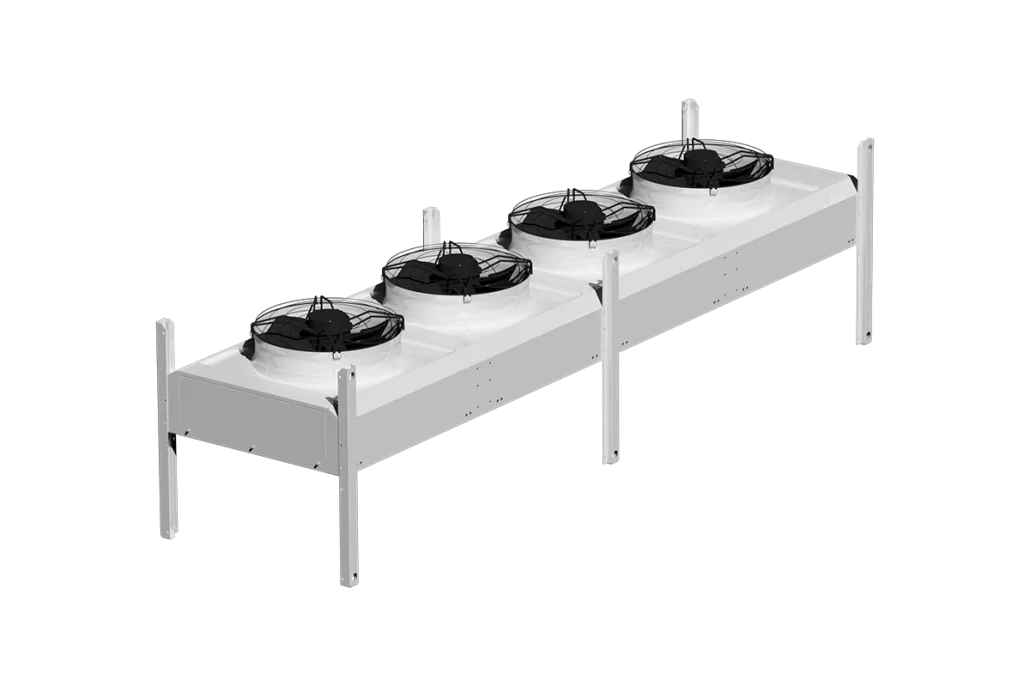

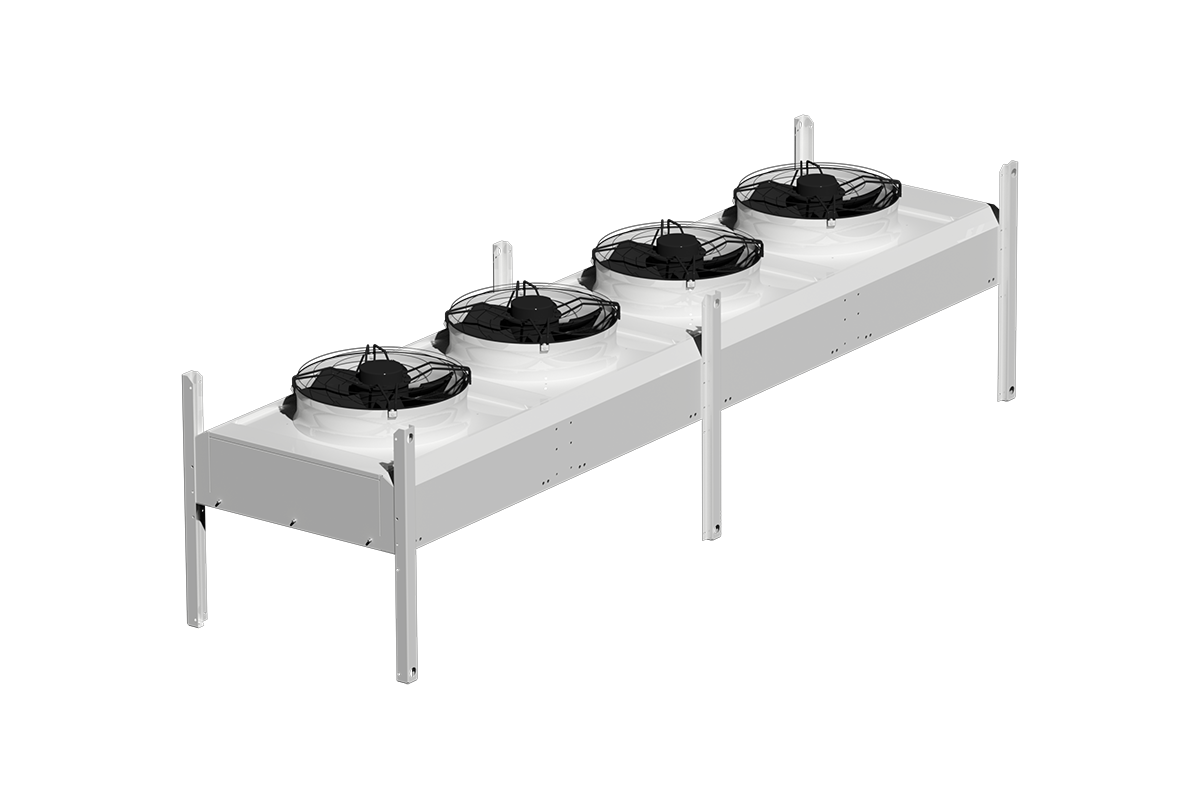

Mistral-F Flatbed Dry Coolers

FEATURES AND ADVANTAGES

- Designed for water, glycols, special fluids

- Leading energy efficiencies

- Space-saving, low-noise design

- Intelligent fan speed control

- Corrosion-resistant coatings for heat exchangers

Mistral-V Compact V-Shaped Dry Coolers

FEATURES AND ADVANTAGES

- Designed for water, glycols, special fluids

- Low-height design

- Intelligent fan speed control

- Evaporative pre-cooling

- Adiabatic spray system

- Corrosion-resistant coatings for heat exchangers

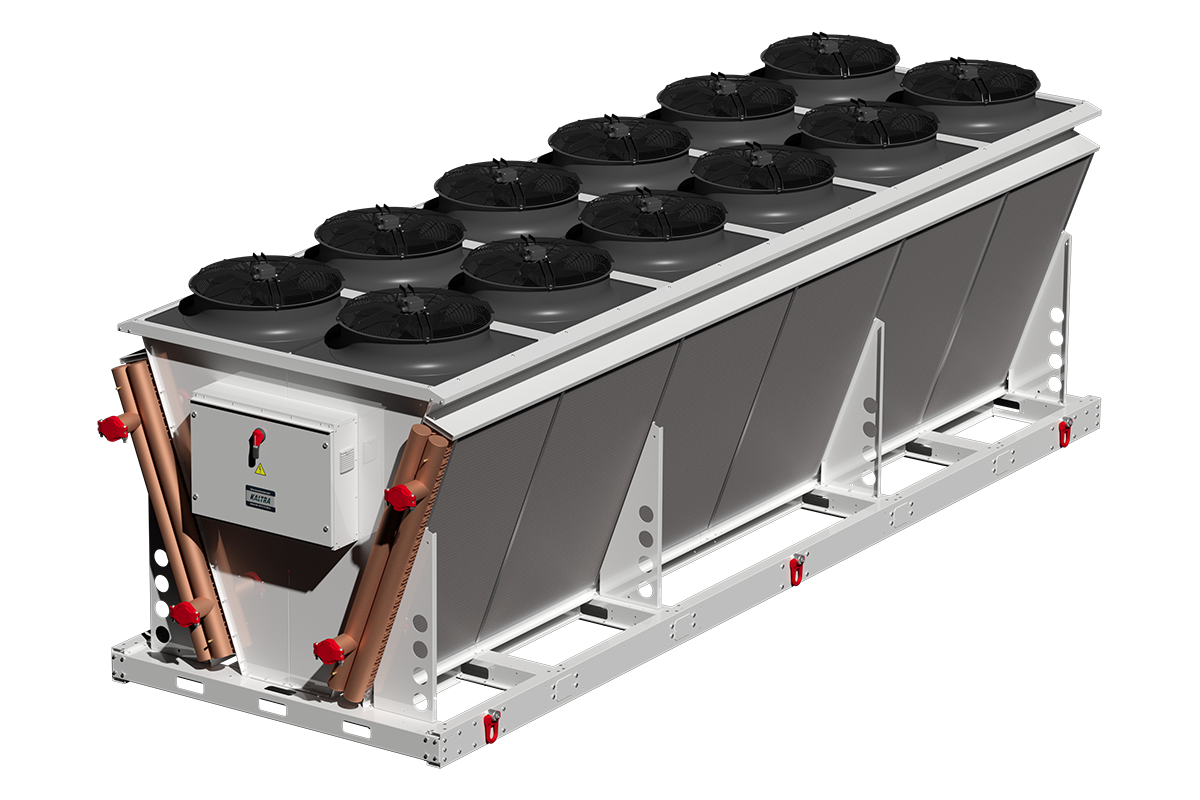

Mistral-W High-Performance Dry Coolers

FEATURES AND ADVANTAGES

- Designed for water, glycols, special fluids

- High capacity up to 2MW

- Evaporative pre-cooling

- Adiabatic spray system

- Intelligent fan speed control

- Corrosion-resistant coatings for heat exchangers

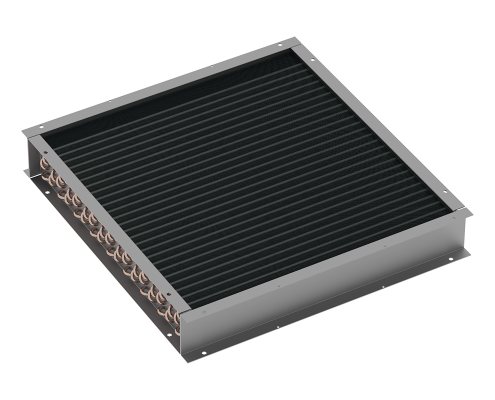

Enhanced Heat Exchangers

Mistral dry coolers feature upgraded heat exchangers with reduced internal volume, aluminium fins with 25% increased thickness, and inner grooved copper tubes, which facilitate more efficient heat transfer through an inner surface area increased in size by 65%. The groove’s torsion promotes turbulent flow, resulting in improved tubeside heat transfer characteristics.

Copper tubes manufactured using the new pressure expansion method show significant improvements over traditional mechanical expansion methods and feature improved tube-fin contact, higher strength for resisting internal pressure, and enhanced overall heat transfer performance for a coil.

Available heat exchanger treatments include pre-painted fins, hydrophilic and hydrophobic coatings, and electrophoretic epoxy paint.

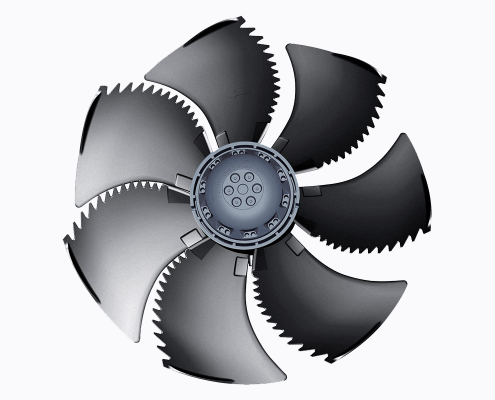

Quiet and Efficient Axial Fans

Mistral dry coolers have fans with alternating current (AC) motors as a standard, and fans with electronically commutated (EC) motors as an option; fan diffusers and selection of three sound level grades giving customers the choice of a bespoke solution that suits their requirements.

Mistral dry coolers can be supplied in three noise intensity designs: standard, low-noise, and ultra-low noise levels. Low sound emission level allows installation in populated urban areas and everywhere where low noise pollution is an essential factor.

PRODUCT SPECIFICATIONS

| Capacity [kW] | 10 … 2000 |

|---|---|

| Fan quantity | 1 … 18 |

| Fan motors | AC/EC |

| Evaporative pre-cooling | AVAILABLE |

| Adiabatic spray system | AVAILABLE |

| Low-noise models | AVAILABLE |

| Heat exchangers | RTPF |

| Protective coatings | AVAILABLE |

| Refrigerants | WATER/BRINE |

| Warranty | 3 YEARS |