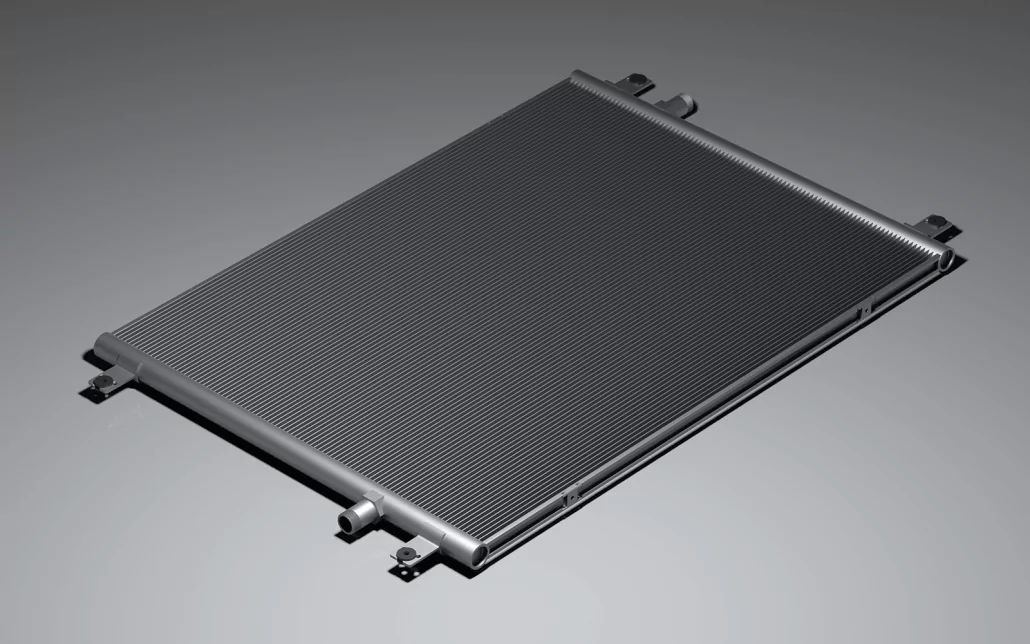

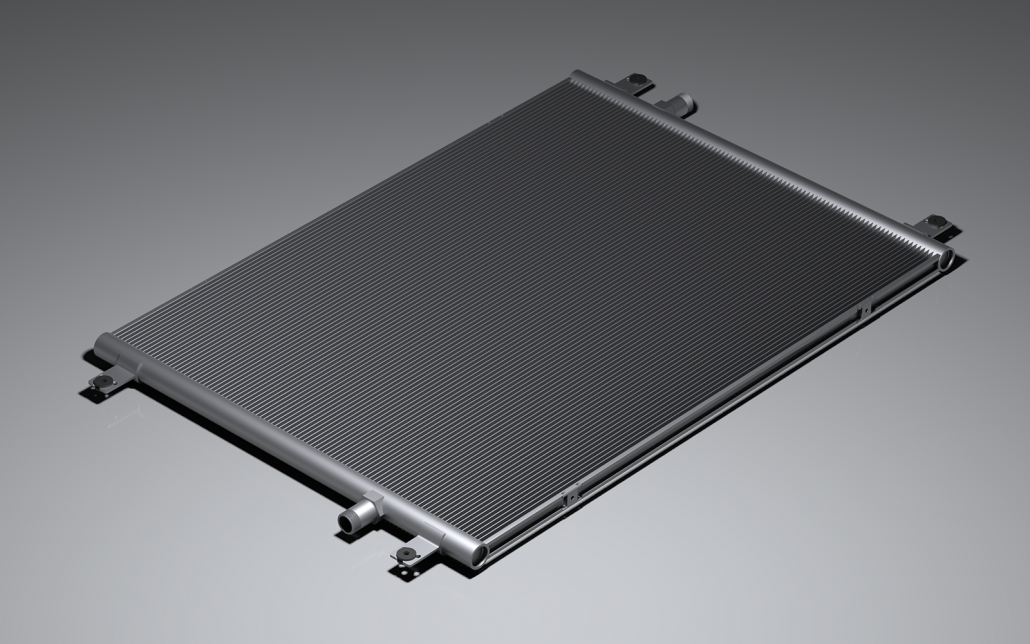

DESIGN AND STRUCTURE

The heat exchanger core is all-aluminum, integrally brazed in a controlled-atmosphere brazing (CAB) furnace; the assembly includes the following elements:

- Parallel microchannel tubes and fin strips, selected individually as per customer requirements

- Inlet and outlet manifolds

- Reinforcement bars

- Water inlet and outlet connections

- Mounting brackets with vibration/corrosion isolators

- Mounting studs

FEATURES AND ADVANTAGES

End-users and OEMs can benefit from the advantages inherent in the design of air-to-water microchannel coils. Compared to the finned tube (RTPF) heat exchangers, microchannel water coils (MCHE) demonstrate significant improvements in performance and efficiency

Applications

Our microchannel water coils are multi-purpose heat exchangers designed for air-to-water applications: chilled water coils, free cooling coils, dry coolers, heating coils, pumped loop evaporators, gas cooling and heating, and for special applications.

Dimensioning

Flexibility and variable dimensions are tailored to OEM customer requirements using our selection software. Custom and standard sizes are available from as small as 50x50mm to over 6000x2000mm with a broad selection of microchannel tubes, fin pitches, and more.

Connections

All microchannel water coils have options for aluminium, steel, or copper connections of different diameters and types for piping, fit-up, and easy packaging. All connection options are available using our selection software.

Protection

Beyond the usage of long-life aluminium alloys, we offer electrophoretic painting or trivalent chrome process treatment for added heat exchanger corrosion resistance. The coatings ensure a long operating lifespan even for seashore applications and installations in high-polluted areas.

SELECTION SOFTWARE

MCHE selection software includes condenser, evaporator, heat pump, and water coils, making it a complete selection and calculation tool for refrigeration professionals.

The software provides selections and ratings for microchannel heat exchangers which enables the user to select the best-suited product based on several deciding parameters such as heat exchanger application, cooling capacity, refrigerant, evaporation and condensation temperatures, airflow and air temperature and other critical variables in refrigeration systems.

PRODUCT SPECIFICATIONS

| Max width [mm] | 50 … 6000 |

|---|---|

| Max height [mm] | 50 … 2000 |

| Tube width [mm] | 12/16/18/20/22/25/32/36 |

| Manifold diameter [mm] | 16/20/25/28/30/32/38/42/50 |

| Fin types | FLAT/LOUVERED |

| Fin pitches [FPI] | 10/16/18/19/21/23/24/BY REQUEST |

| Design pressure [bar] | 20 |

| Refrigerants | WATER/GLYCOLS/SPECIAL |

| Protective coatings | E-COATING/TCP-COATING/HYDROPHILIC |