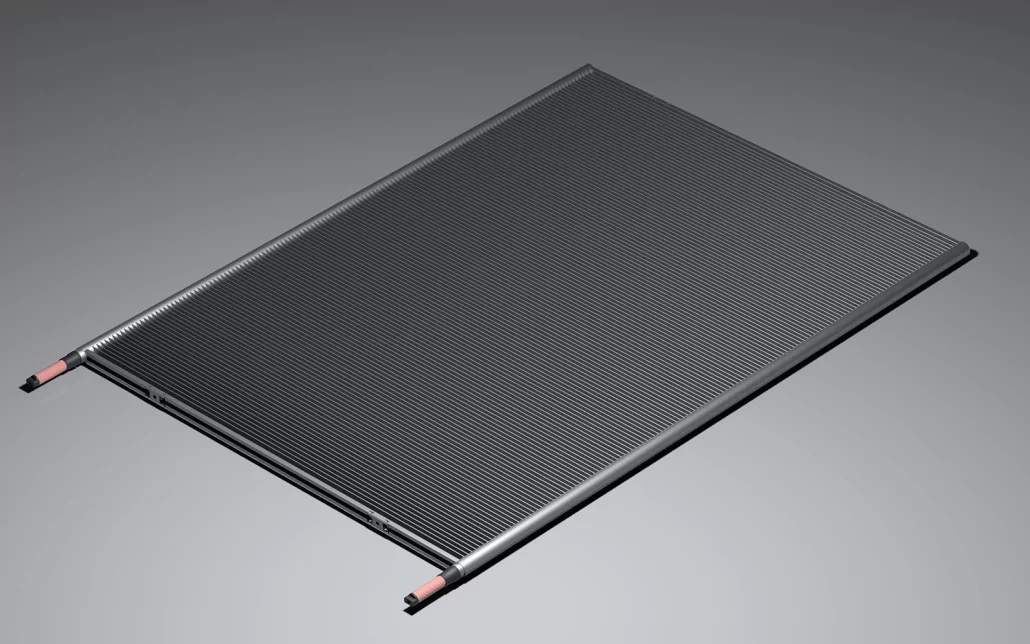

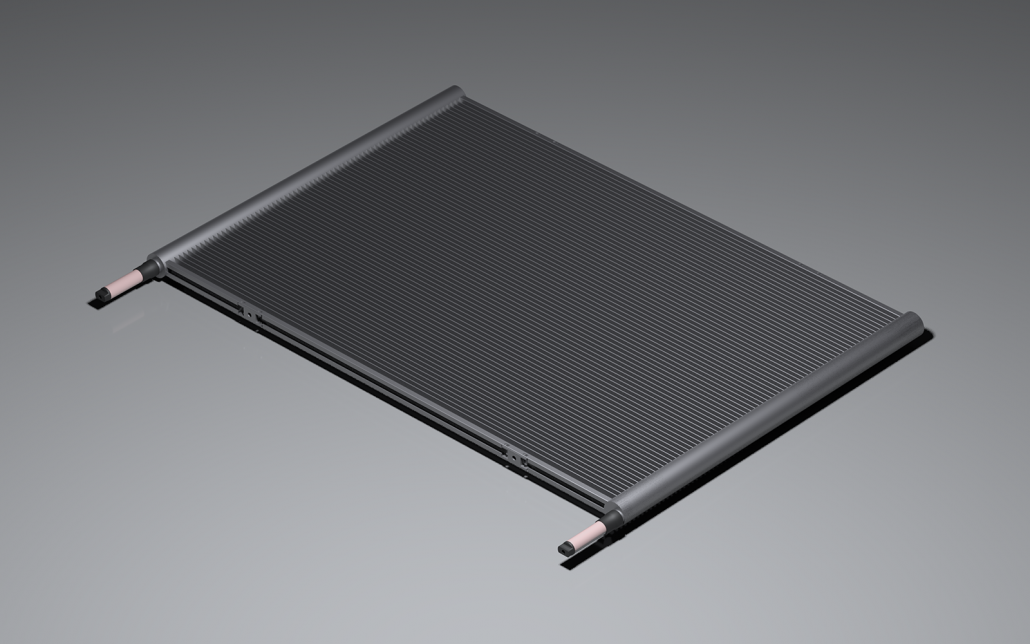

EVAPORATOR DESIGN

The new generation microchannel evaporator significantly differs from other types in many ways; its construction includes the following elements:

- Parallel microchannel tubes and fin strips, selected individually as per customer requirements

- Inlet manifold with an integrated refrigerant distributor providing even refrigerant distribution across the microchannel tubes

- Outlet manifold

- Refrigerant inlet and outlet connections

- Reinforcement bars

- Mounting studs

FEATURES AND ADVANTAGES

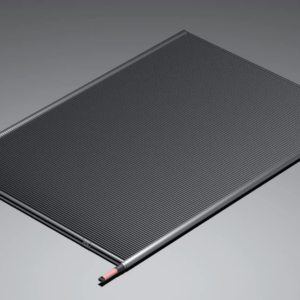

Our evaporator coils have been designed for high performance and efficiency to cope with sensible and latent heat. Design versatility allows operating this type of heat exchangers in reverse as a condenser.

LESS REFRIGERANT CHARGE

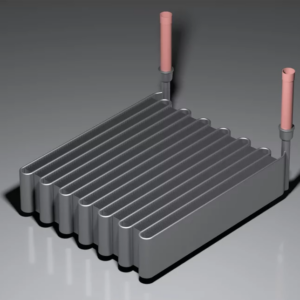

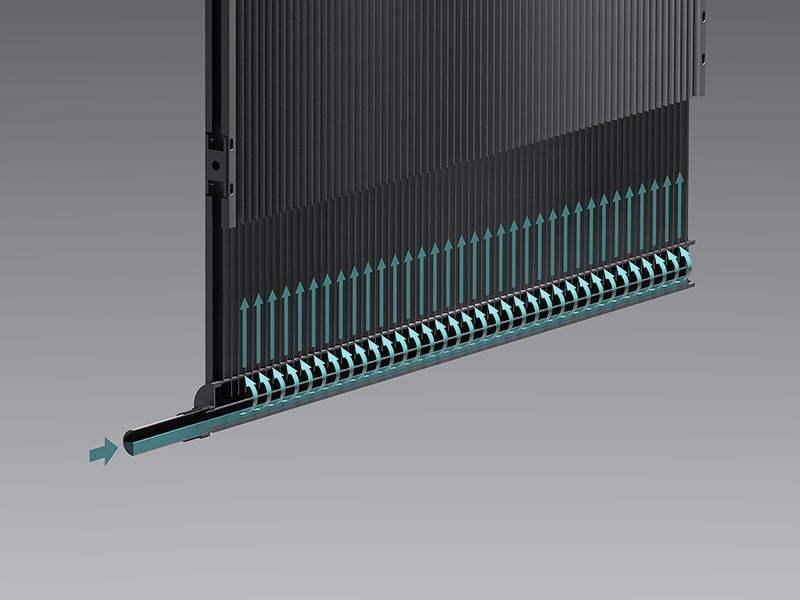

Refrigerant Distributor: How It Works

The primary function of the DX distributor integrated into the inlet manifold of the evaporator coil is uniform refrigerant spreading across the length of the coil, over a wide range of operating conditions and equipment designs. The distributor provides:

- Liquid/gas separation of the mixture delivered to the distributor

- Injection of liquid refrigerant into distributor orifices and creation of pressure drop to propel the refrigerant and to spread out the liquid substantially evenly along the length of the inlet manifold

- Injection of liquid refrigerant into the tube chambers

- Prevention of refrigerant flow between refrigerant tube chambers before entering the microchannel tube ports

SELECTION SOFTWARE

MCHE selection software includes condenser, evaporator, heat pump, and water coils, making it a complete selection and calculation tool for refrigeration professionals.

The software provides selections and ratings for microchannel heat exchangers which enables the user to select the best-suited product based on several deciding parameters such as heat exchanger application, cooling capacity, refrigerant, evaporation and condensation temperatures, airflow and air temperature and other critical variables in refrigeration systems.

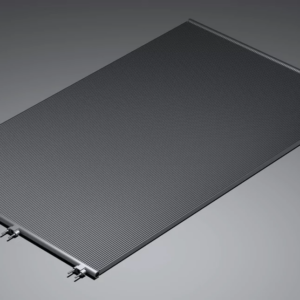

PRODUCT SPECIFICATIONS

| Max width [mm] | 50 … 2400 |

|---|---|

| Max height [mm] | 50 … 2400 |

| Tube width [mm] | 12/16/20/25/32/36 |

| Manifold diameter [mm] | 16/20/25/30/32/38/42/50 |

| Fin types | FLAT/LOUVERED |

| Fin pitches [FPI] | 10/16/18/19/21/23/24/BY REQUEST |

| Design pressure [bar] | 32/45 |

| Refrigerants | HFC/HFO/NATURAL |

| Protective coatings | E-COATING/TCP-COATING/HYDROPHILIC |