FEATURES AND ADVANTAGES

Microchannel condensers have a number of advantages over traditional finned tube designs that significantly improve HVAC systems’ performance:

- Up to 40% higher heat transfer efficiency

- Lower airside pressure drops

- Closer approach temperatures

- Up to 20% smaller coil face area

- Less weight – up to 50%

- Less refrigerant charge: typically 40% to 60%

High Corrosion Resistance

Our heat exchangers – made from new, long-life aluminium alloys – demonstrate excellent corrosion resistance, even in highly salted marine atmospheres or chemically-polluted areas.

High corrosion resistance proved by numerous SWAAT ASTM G-85 Annex A3 tests where specimens have been exposed to a continuous spray of acidified water solutions under high humidity and temperature for more than 3000 hours.

Protective coatings we offer, such as electrophoretic painting or trivalent chrome process treatment, further strengthen the resistance to corrosion and guarantee times longer operating life of the heat exchangers.

Optimized Part-Load Operation

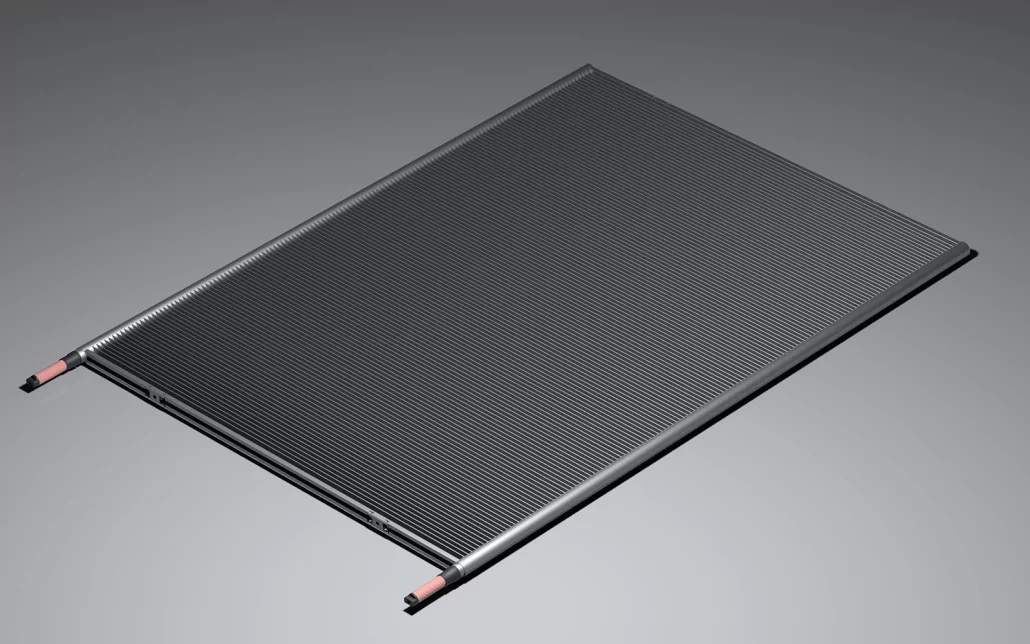

In microchannel condensers with vertical tube arrangement, the lower manifold acts as a receiver and accumulates and holds liquid refrigerant. The lower manifold has an internal outlet baffle to allow only liquid refrigerant to leave the heat exchanger and to hold back refrigerant gas. Accordingly, an excess refrigerant charge is allowed to back-up into the lower manifold, and help optimize the system charge.

The most important, built-in refrigerant receiver acts to optimize the part-load operation, which is crucial to engineering the modern refrigeration and cooling equipment.

Precise Engineering

In the design of a microchannel heat exchanger, every detail plays its role, contributing to its overall efficiency. An example of this is the geometry of louvered fins: a precise selection of pitch, inclination angle, and arrangement of fin louvers lead to the optimum balance between airflow resistance and heat transfer rates in our heat exchangers.

Based on the performance and other customer requirements, we perform a thorough analysis to identify the most suitable combination of heat exchanger elements and materials. Having at disposal an extensive nomenclature of components, raw materials, advanced production machinery and brazing furnaces, we manufacture state-of-the-art heat exchangers and help customers improve the efficiency and performance of their end equipment.

SELECTION SOFTWARE

MCHE selection software includes condenser, evaporator, heat pump, and water coils, making it a complete selection and calculation tool for refrigeration professionals.

The software provides selections and ratings for microchannel heat exchangers which enables the user to select the best-suited product based on several deciding parameters such as heat exchanger application, cooling capacity, refrigerant, evaporation and condensation temperatures, airflow and air temperature and other critical variables in refrigeration systems.

PRODUCT SPECIFICATIONS

| Max width [mm] | 50 … 6000 |

|---|---|

| Max height [mm] | 50 … 2000 |

| Tube width [mm] | 12/16/20/25/32/36 |

| Manifold diameter [mm] | 16/20/25/30/32/38/42/50 |

| Fin types | FLAT/LOUVERED |

| Fin pitches [FPI] | 10/16/18/19/21/23/24/BY REQUEST |

| Design pressure [bar] | 32/45 |

| Refrigerants | HFC/HFO/NATURAL |

| Protective coatings | E-COATING/TCP-COATING/HYDROPHILIC |