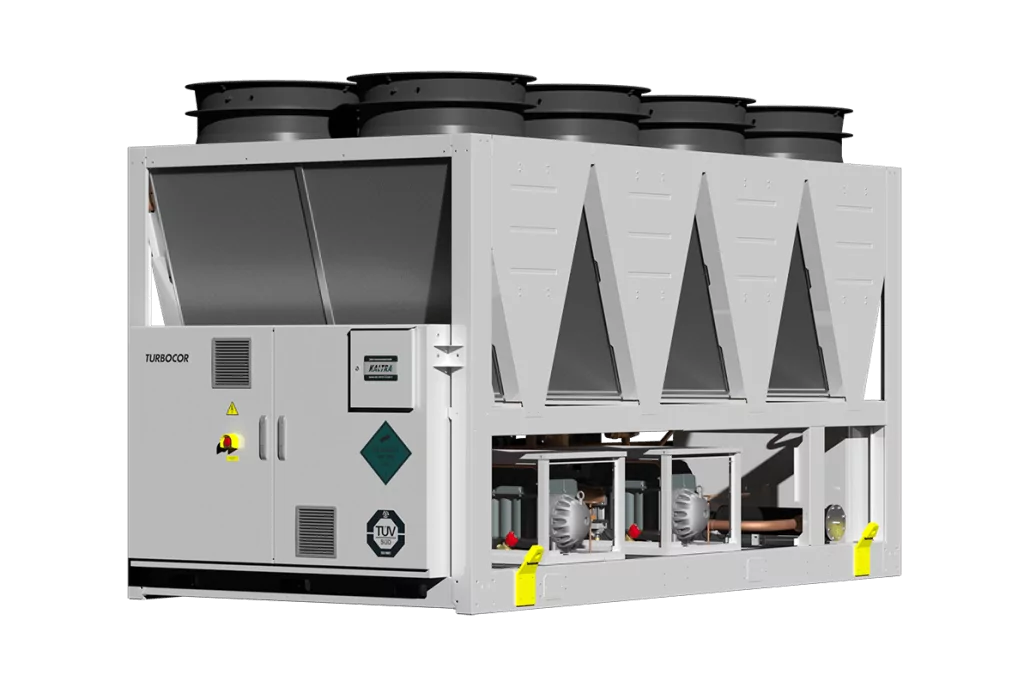

DEMAND-RESPONSIVE CHILLERS WITH TURBOCOR COMPRESSORS

Lightstream Turbo chillers were designed with attention to every detail to maximize performance and fit ideally to the requirements of mission-critical applications like data centers, telecom facilities and clean rooms, and in every area where efficiency and reliability are crucial factors.

Due to its excellent efficiency under part-load conditions, Lightstream Turbo chillers are the brilliant economy solution for applications where the heat load is not constant or expected to increase. Proposed with lower GWP refrigerant R1234ze, it is also an environment-safe solution, compliant with the latest legislation.

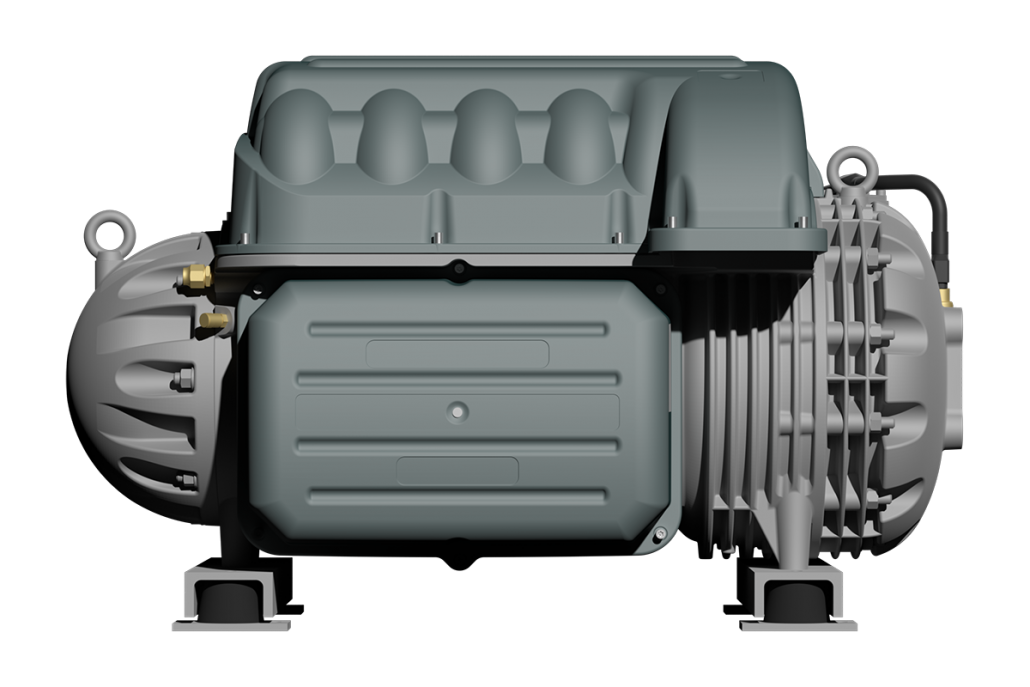

TURBOCOR COMPRESSORS

EXCELLENT ENERGY EFFICIENCY AND UP TO 25% SAVINGS IN OPERATING COSTS

Turbocor compressors offer outstanding energy savings from digitally controlled, frictionless two-stage centrifugal compression and guarantee significant reductions in operating cost at full and partial loads – thank permanent magnet motor and variable speed drive.

Oil-free design of Turbocor compressors eliminates the potential for efficiency-robbing oil contamination and all of the oil management accessories: oil heaters, oil pumps, separators, filters, plus oil disposal. Furthermore, oilless design excludes chiller performance degradation.

Turbocor compressor draws only two amps at startup and reduces mechanical stress, as well as the electrodynamic stresses on the power cables and electrical distribution network, extending the overall lifespan of the system.

MICROCHANNEL CONDENSERS

With the incorporation of microchannel condensers, Lightstream Turbo provides owners all the numerous benefits of this technology, permits a substantial increase in cooling efficiency and enables improvements in chiller design and it’s environmental safety – compared to finned tube coil designs:

- Higher heat transfer rates enable lower condensing temperatures and result in energy savings on compressors

- Low air resistance leads to reduced fan power consumption and lower noise output

- High corrosion resistance of all-aluminum heat exchanger construction increases the service life of the chillers

- Straight airflow path results in less fouling and clogging of heat exchangers

- Lower refrigerant charge, up to 50%

- Reduced size and weight which translates to lower costs of the chiller

Optionally available protective coatings enable trouble-free condenser operation in marine atmospheres, high-polluted industrial zones, and other chemically active areas.

EXTRA CONDENSER SECTIONS FOR HIGHER EFFICIENCY

Lightstream Turbo H-series chillers feature extra condenser banks to enable lower condensing temperatures and offer 15% higher energy efficiencies compared to standard models and reduced noise levels.

ENVIRONMENT-FRIENDLY REFRIGERANTS

R1234ZE

Refrigerants with low global warming potential (GWP) are becoming more and more important in the refrigeration and air conditioning industry in Europe and beyond.

R1234ze features low GWP of one and zero ozone depletion potential, thus providing the environmental leadership for Lightstream Turbo chillers while achieving the best energy performance levels for applications.

HIGH-EFFICIENT FANS

AXIAL FANS WITH REDUCED POWER CONSUMPTION

Lighstream Turbo’s new generation fan system not only reduces power consumption by up to 30% while managing high volume flows, but it also works at significantly reduced operating noise levels.

The smart fan system includes axial fans with bionic wing concept, the most advanced EC motor technology, and multifunctional air diffusers, resulting in economic efficiency for customers.

EC motor technology not only produces savings in full-load operation – it is exactly when operating under partial load that EC motors lose much less of their efficiency.

EVAPORATORS

The design of the Lightstream Turbo evaporators provides optimum system efficiency at both full and partial load operation. The tubes in flooded evaporator are fully immersed in liquid refrigerant and enable a smaller approach temperature between the refrigerant temperature in its shell and chilled water temperature in the tubes to be achieved. With a flooded evaporator, the compressors operate at higher saturated evaporation temperatures and generate more cooling capacity with the same power input.

FREE COOLING

GENERATE ENERGY SAVINGS ALL YEAR ROUND

Lightstream Turbo chillers can supply chilled water with relatively high temperatures, thus maximizing the amount of time the system can produce chilled water without running the mechanical cooling mode. Compared to air-cooled models, Lightstream Turbo equipped with a free cooling system generates energy savings of up to 50% and returns investments within a short timeframe.

When running in concurrent free cooling and mechanical cooling mode, the control system continually monitors the condensing temperature and keeps it within the scope of the compressor to allow the maximum possible fan speed and achieve the maximum free cooling. During periods when the fan speed has to be reduced to a minimum, the chilled water temperature is controlled via motorized valves.

PRODUCT SPECIFICATIONS

| Capacity [kW] | 300 … 1600 |

|---|---|

| Design | AIR-COOLED |

| Compressors | TURBOCOR |

| Refrigerant | R134A/R1234ZE |

| Energy efficiency (EER) | UP TO 4.30 |

| Seasonal efficiency (ESEER) | UP TO 5.90 |

| Fan motors | EC |

| Condensers | MCHE |

| Evaporators | FLOODED S&T |

| Evaporation control | EEV |

| Refrigeration circuits | SINGLE |

| Warranty | 3 YEARS |