CHILLERS IN CLASS A ENERGY EFFICIENCY

Efficient air-cooled scroll chillers offering a wide range of cooling capacities and options, including partial and total heat recovery, integrated hydronic pump packages, and more.

Lightstream Scroll chiller family combines cost-effective, quiet in operation scroll compressors and the latest axial fan technology applied in modular V-form coil design. Microchannel heat exchangers significantly increase efficiency, whilst the refrigerant charge is relatively low.

With advanced HVAC technologies found in its design, the Lightstream Scroll chiller provides stable cooling and costs less to purchase and operate compared to other chillers in its class.

SCROLL COMPRESSORS

MULTI-COMPRESSOR, MULTI-CIRCUIT TECHNOLOGY

Lighstream Scroll chillers incorporate scroll compressors in tandem configuration, which offer part-load efficiency and increased load-matching capabilities, together with quiet operation and diagnostic capabilities, and enable two-stage capacity by running compressors individually or simultaneously.

Lightstream’s refrigerant side consists of one to four gas circuits – depending on unit capacity, each equipped with electronic expansion valve (EEV) to ensure optimum head pressure control. Depending on requirements, customers can choose from partial or total heat recovery features.

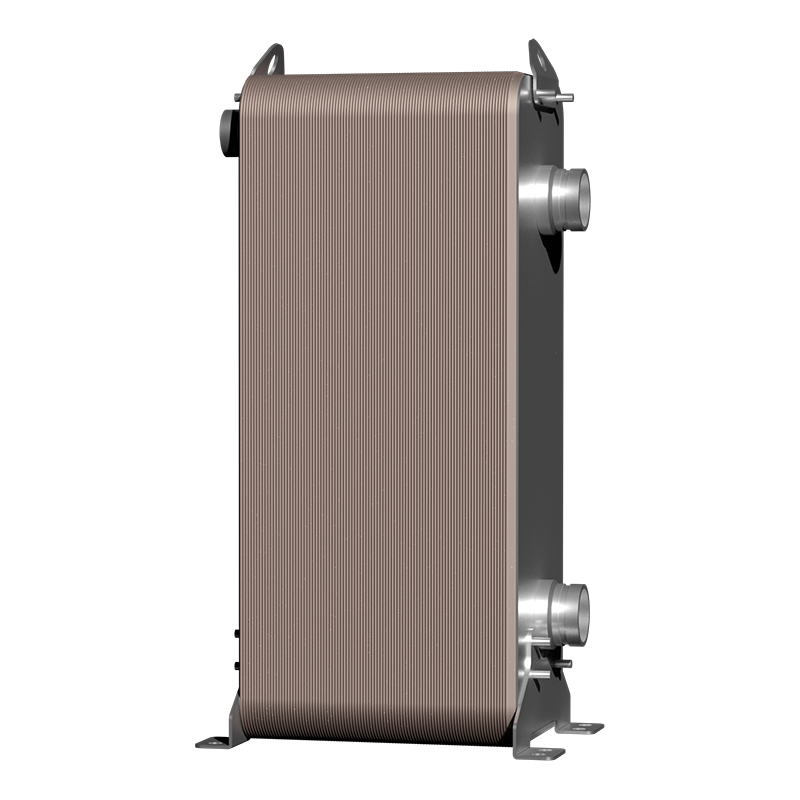

EVAPORATORS

Lighstream Scroll chillers feature either brazed plate or shell-and-tube heat exchangers, depending on unit capacity and end-customer preference.

BRAZED PLATE HEAT EXCHANGERS

Brazed plate heat exchangers provide optimal heat transfer efficiency, pressure resistance and longest possible service lifetime, guaranteed by their advanced design. Low internal volume – compared to other types of heat exchangers – permits refrigerant charge reduction to a minimum.

SHELL-AND-TUBE HEAT EXCHANGERS

Shell-and-tube heat exchangers with an innovative refrigerant distributor and optimized plastic baffles are designed to improve the waterside heat transfer performance. The tubes have a specific inner-grooved pattern to maximize the heat transfer coefficient and to limit the pressure drop negative effects. This type of evaporators is recommended for optimum efficiency.

HIGH-EFFICIENT FANS

AXIAL FANS WITH REDUCED POWER CONSUMPTION

Lighstream Scroll’s new generation fan system not only reduces power consumption by up to 30% while managing high volume flows, but it also works at significantly reduced operating noise levels.

The smart fan system includes axial fans with bionic wing concept, the most advanced EC motor technology, and multifunctional air diffusers, resulting in economic efficiency for customers.

EC motor technology not only produces savings in full-load operation – it is exactly when operating under partial load that EC motors lose much less of their efficiency.

MICROCHANNEL CONDENSERS

With the incorporation of microchannel condensers, Lightstream Scroll provides owners all the numerous benefits of this technology, permits a substantial increase in cooling efficiency and enables improvements in chiller design and it’s environmental safety – compared to finned tube coil designs:

- Higher heat transfer rates enable lower condensing temperatures and result in energy savings on compressors

- Low air resistance leads to reduced fan power consumption and lower noise output

- High corrosion resistance of all-aluminum heat exchanger construction increases the service life of the chillers

- Straight airflow path results in less fouling and clogging of heat exchangers

- Lower refrigerant charge, up to 50%

- Reduced size and weight which translates to lower costs of the chiller

Optionally available protective coatings enable trouble-free condenser operation in marine atmospheres, high-polluted industrial zones, and other chemically active areas.

OPTIONAL EXTRAS

PRODUCT SPECIFICATIONS

| Capacity [kW] | 200 … 900 |

|---|---|

| Design | AIR-COOLED |

| Compressors | SCROLL |

| Refrigerant | R410A |

| Energy efficiency (EER) | UP TO 3.20 |

| Seasonal efficiency (ESEER) | UP TO 4.70 |

| Fan motors | AC/EC |

| Condensers | MCHE |

| Evaporators | BPHE/S&T |

| Evaporation control | EEV |

| Refrigeration circuits | SINGLE/MULTIPLE |

| Warranty | 3 YEARS |