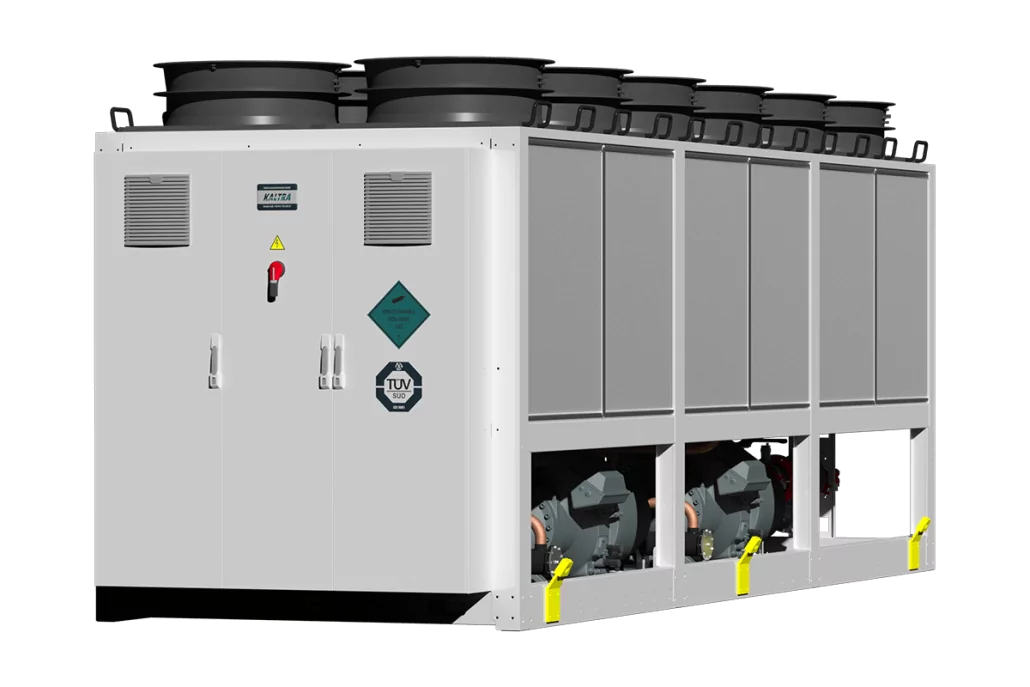

PERFECT FOR VARIABLE-DEMAND COOLING APPLICATIONS

Lightstream Screw-W Inverter chillers deliver efficient operation by adjusting the compressor speed to actual cooling demand. Combined with the latest condenser technology and close approach evaporators, these R134a/R1234ze-based chillers offer decreased energy consumption and stable supply water temperatures, particularly at partial load under low water temperature conditions, and help customers to reduce operating expenses and environmental impact.

In addition, the chillers have many unique options and accessories which satisfy the customers’ demand to design tailored solutions.

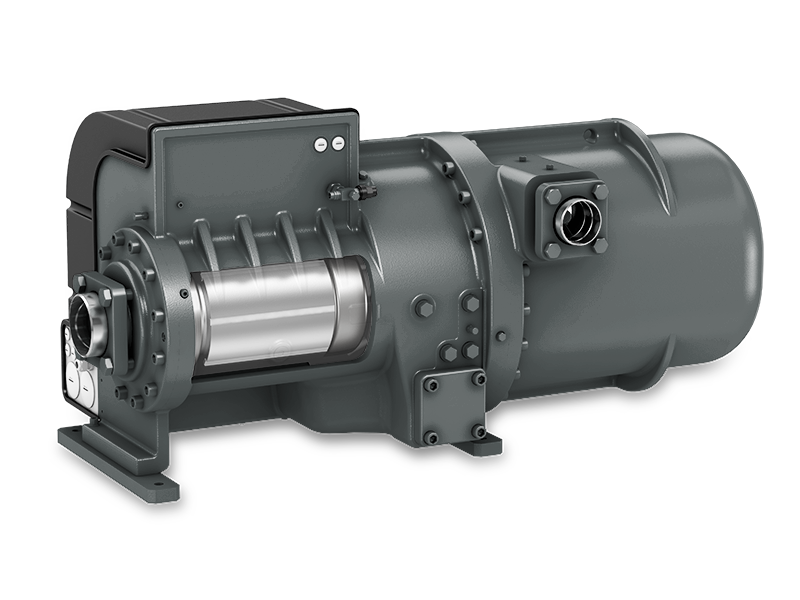

INVERTER SCREW COMPRESSORS

EXACT CAPACITY MATCH AND LARGE REDUCTION IN RUNNING COSTS

Lightstream’s screw compressors with frequency-controlled capacity adjustment are optimized for maximum efficiency in air-cooled chillers. These compressors are especially suitable for systems that frequently operate under part-load and feature an integrated frequency inverter which controls the motor speed – enabling infinite capacity control for customers and optimal energy use in applications.

These compressors achieve impressively high full-load efficiency and significantly improved ESEER/IPLV and SCOP values: with an average ESEER value above 5.5, Lighstream Screw chillers are setting new benchmarks for air-cooled chillers in the industry.

The compressor monitors its own application limits and communicates via Modbus with the master chiller controls. The integrated data log can be used at any time to analyze operation over the running time and optimize the system settings. The integrated soft-start feature facilitates the steady increase of the in-rush current without voltage spikes.

MICROCHANNEL CONDENSERS

With the incorporation of microchannel condensers, Lightstream Screw-W Inverter provides owners all the numerous benefits of this technology, permits a substantial increase in cooling efficiency and enables improvements in chiller design and it’s environmental safety – compared to finned tube coil designs:

- Higher heat transfer rates enable lower condensing temperatures and result in energy savings on compressors

- Low air resistance leads to reduced fan power consumption and lower noise output

- High corrosion resistance of all-aluminum heat exchanger construction increases the service life of the chillers

- Straight airflow path results in less fouling and clogging of heat exchangers

- Lower refrigerant charge, up to 50%

- Reduced size and weight which translates to lower costs of the chiller

Optionally available protective coatings enable trouble-free condenser operation in marine atmospheres, high-polluted industrial zones, and other chemically active areas.

INTELLIGENT FAN SYSTEM

EC-FANS WITH REDUCED POWER CONSUMPTION

Our new generation fan system not only reduces power consumption by up to 30% while efficiently managing high volume flows – but it also works at much reduced operating noise. The smart fan system includes the unique fan impellers with bionic wing concept, the most advanced EC-motor technology, and multifunctional air diffusers, resulting in an extra efficiency for the customers.

EC-motors use commutation electronics to sense the rotor position and adjust supply current, thus eliminating the need for mechanical brushes to deliver current to the motor windings. Elimination of physical contact reduces internal wear within the fan motor and significantly increases reliability.

EC-motor technology provides savings during full-load operation, as well as under partial loads when EC motors lose much less of their efficiency compared to AC fans.

REFRIGERANT R1234ZE

ENVIRONMENT-FRIENDLY, LOW-GWP SOLUTION

The proposed phase-down of HFC refrigerants has prompted an assessment of alternative fluids for a wide range of applications, including medium-temperature air-cooled chillers.

Recently developed R1234ze refrigerant features low global warming potential and zero ozone depletion potential and fulfills EU regulatory requirements for reducing the use of high global warming potential (GWP) substances. At the same time, R1234ze almost strictly matches the efficiency of R134a.

With R1234ze, Lightstream Screw-W Inverter chiller provides environmental leadership while achieving the best energy performance levels for applications.

EVAPORATORS

The design of the Lightstream Screw-W Inverter evaporators provides optimum system efficiency at both full and partial load operation. The tubes in flooded evaporator are fully immersed in liquid refrigerant and enable a smaller approach temperature between the refrigerant temperature in its shell and chilled water temperature in the tubes to be achieved. The refrigerant pool behaves as a flywheel, allowing the controls of the evaporator to track the varying load of a batch process, while optimized tube geometry ensures optimal refrigerant distribution.

With a flooded evaporator, the compressors operate at higher saturated evaporation temperatures and generate more cooling capacity with the same power input.

PRODUCT SPECIFICATIONS

| Capacity [kW] | 500 … 1400 |

|---|---|

| Design | AIR-COOLED |

| Compressors | SCREW |

| Refrigerant | R134A/R1234ZE |

| Energy efficiency (EER) | UP TO 3.56 |

| Seasonal efficiency (ESEER) | UP TO 5.75 |

| Fan motors | AC/EC |

| Condensers | MCHE |

| Evaporators | FLOODED S&T |

| Evaporation control | EEV |

| Refrigeration circuits | SINGLE |

| Warranty | 3 YEARS |