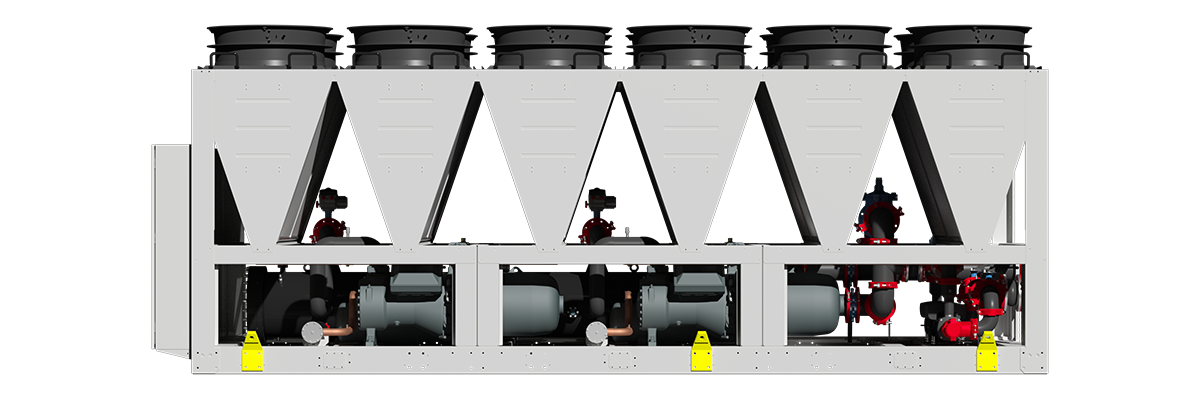

RELIABLE, EFFICIENT, AND ENVIRONMENTALLY SAFE CHILLERS

Lightstream Screw-V is a reliable solution in a broad range of cooling plant capacities, efficiency requirements, and environmental policies. These chillers available in three efficiency grades to match the customer’s demand for power consumption optimization.

The high level of customizability and numerous options, including free cooling and heat recovery, allow the users to adapt these air-cooled chillers to the precise application, be it industrial process, air conditioning, or data center facility. Lightstream Screw-V chillers can operate with either R134a or low-GWP refrigerants R1234ze and R513a.

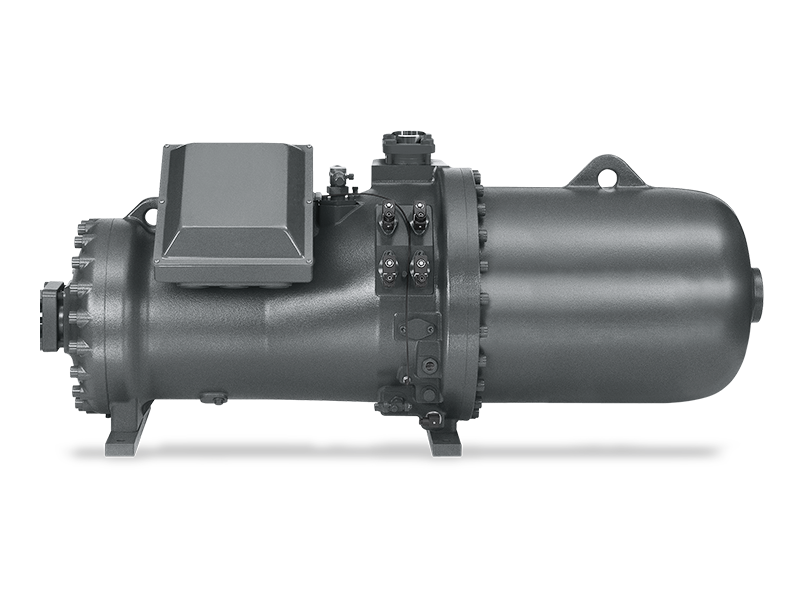

SCREW COMPRESSORS

LATEST SCREW COMPRESSOR TECHNOLOGY WITH CAPACITY CONTROL

Lightstream Screw-V range features compact semi-hermetic screw compressors designed specifically for highly efficient air-cooled chillers and heat pumps for operation with refrigerants R134a, R1234ze, or R513a, and optimized for the ambient temperature profile specified by the Ecodesign Directive for water chillers (European Chiller Energy Efficiency Standard EU 2016/2281 Tier 1, effective from January 2018).

The application limits of the compressors have been substantially extended towards low condensing temperatures as well as to high pressure ratios – without compromises regarding operating reliability.

The compressors feature an integrated oil separation system, economizer technology, and infinite capacity control achieved by changing the control sequence of integrated solenoid valves.

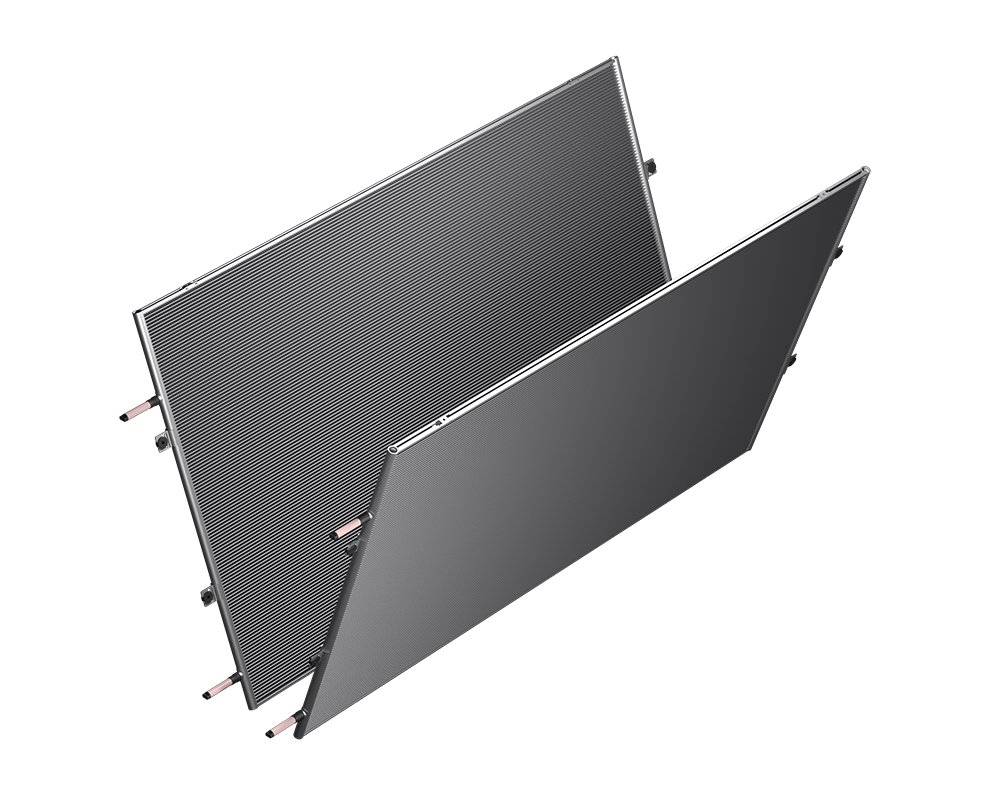

MICROCHANNEL CONDENSER COILS

For Lightstream Screw-V chillers we use microchannel condenser coils of a new design – with optimized louvered fin geometry and microchannel tubes with reduced port size – both made from long-life aluminium alloys. This new design enhances the overall heat transfer while reducing airside pressure drop as compared to coils of the previous generation, thus enabling fan energy savings.

The chillers characterized by noticeably reduced refrigerant charge as new coils have reduced internal volume, and this translates to lower initial and maintenance costs. High heat transfer rates lead to considerable lower condensing temperatures, which in turn enables the savings on compressor energy.

For installations in aggressive or highly-polluted environments, as well as for seashore installations, we recommend e-coated coils with high corrosion resistance to ensure long service life.

INTELLIGENT FAN SYSTEM

EC-FANS WITH REDUCED POWER CONSUMPTION

Our new generation fan system not only reduces power consumption by up to 30% while efficiently managing high volume flows – but it also works at much reduced operating noise. The smart fan system includes the unique fan impellers with bionic wing concept, the most advanced EC-motor technology, and multifunctional air diffusers, resulting in an extra efficiency for the customers.

EC-motors use commutation electronics to sense the rotor position and adjust supply current, thus eliminating the need for mechanical brushes to deliver current to the motor windings. Elimination of physical contact reduces internal wear within the fan motor and significantly increases reliability.

EC-motor technology provides savings during full-load operation, as well as under partial loads when EC motors lose much less of their efficiency compared to AC fans.

EVAPORATORS

INNOVATIVE SHELL-AND-TUBE HEAT EXCHANGERS

For shell-and-tube evaporators, thermal performance and pressure drop are considered as major factors that are directly related to operating costs and overall chiller efficiency. Both thermal performance and pressure drop are dependent on the flow paths and types of baffles used to increase the fluid velocity – by diverting the flow across the tube bundle to obtain higher heat transfer coefficients.

The shell-and-tube evaporators used in Lightstream Screw-V chillers feature both high heat transfer performance, close approach temperatures, as well as low pressure drops, as it combines an innovative tube bundle design and optimized baffle geometry. The net result is improved system performance, as well as tight control of return water temperatures.

FREE COOLING OPTION

GENERATES SAVINGS ALL YEAR ROUND

The Lightstream Screw-V chillers can supply chilled water with fairly high temperatures, thus maximizing the amount of time the system can produce chilled water without running mechanical cooling mode. Compared to conventional chillers, Lightstream Screw-V equipped with freecooling system generates the energy savings of up to 50% and return the investments within a short timeframe.

When running in concurrent freecooling and mechanical cooling mode, the control system constantly monitors the condensing temperature and keep it within the compressor envelope to allow the maximum possible fan speed and achieve the most freecooling. During the periods when the fan speed must be reduced to a minimum, the chilled water temperature is controlled via motorized valves.

LOWER GWP REFRIGERANTS

REFRIGERANTS R513A AND R1234ZE

The ongoing phase-out of HFC refrigerants has prompted an assessment of alternative fluids for a wide range of applications, including medium-temperature chillers.

Recently developed refrigerant R1234ze features low global warming potential and zero ozone depletion potential and fulfills EU regulatory requirements for reducing the use of high global warming potential (GWP) substances. At the same time, R1234ze almost exactly matches the efficiency of R134a. R513a is an azeotropic low-GWP, and non-ozone depleting refrigerant based on hydrofluoro-olefin (HFO), developed to replace R134a. Its energy efficiency and capacity match those for R134a, while its environmental impact significantly reduced.

With low-GWP refrigerants, Lightstream Screw-V chiller is the environmentally-friendly leader of the range, while achieving the best energy performance levels for applications.

HYDRONIC MODULES

CIRCULATION PUMPS

Lightstream Screw-V chillers can be equipped with factory-installed variable or fixed-speed pumps. The pumps feature reduced life-cycle costs, optimized efficiency, and high standard of corrosion protection thanks to cataphoretic coating. Variable-speed pumps have a broad performance range, which enables them to perform efficiently under widely varied conditions and to meet a wide range of requirements.

Based on the required performance, customers may select from inline – single or twin – or end-suction pumps installed in soundproof enclosures.

FLOW CONTROL

Chillers can be configured for constant or variable flow depending on a configuration of chilled water system. For the systems with a primary-only circuit, constant pressure differential or constant temperature differential flow control can be selected, while constant temperature differential control is available for primary/secondary systems. Flow control logic dynamically adjusts the pump speed based on the actual load, thus optimizing pump energy consumption and ensuring the stable operation of the chilled water plant.

PRODUCT SPECIFICATIONS

| Capacity [kW] | 200 … 1800 |

|---|---|

| Design | AIR-COOLED/FREE COOLING |

| Compressors | SCREW |

| Refrigerant | R134A/R450a/R513A/R1234ZE |

| Energy efficiency (EER) | UP TO 3.42 |

| Seasonal efficiency (ESEER) | UP TO 4.52 |

| Fan motors | AC/EC |

| Condensers | MCHE |

| Free cooling coils | MCHE |

| Evaporators | SHELL&TUBE |

| Evaporation control | EEV |

| Refrigeration circuits | SINGLE/MULTIPLE |

| Warranty | 3 YEARS |