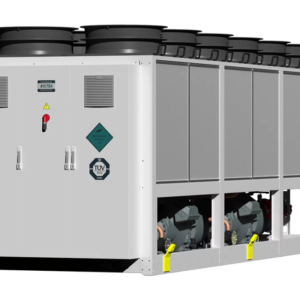

DESIGNED FOR EFFICIENCY, FLEXIBILITY, AND SUSTAINABILITY

Energy savings are one of the most prominent benefits of Lightstream Screw II Inverter chillers designed with variable-speed compressors – thanks motors controlled using frequency modulation by DC inverter allowing chiller to run at lower speeds under part-load conditions. The long list of advantages also includes precise thermal control, lower noise emissions, fast restart, inrush current draw of just a few amps, reduced mechanical stress on all chiller components translating to longer life expectancy, and more.

The range offers an array of options to tailor and tune to match the cooling capacity, efficiency, footprint, sound of a specific application. The control software can manage multiple-chiller installations to achieve the best performance and efficiency for the cooling plant as a whole.

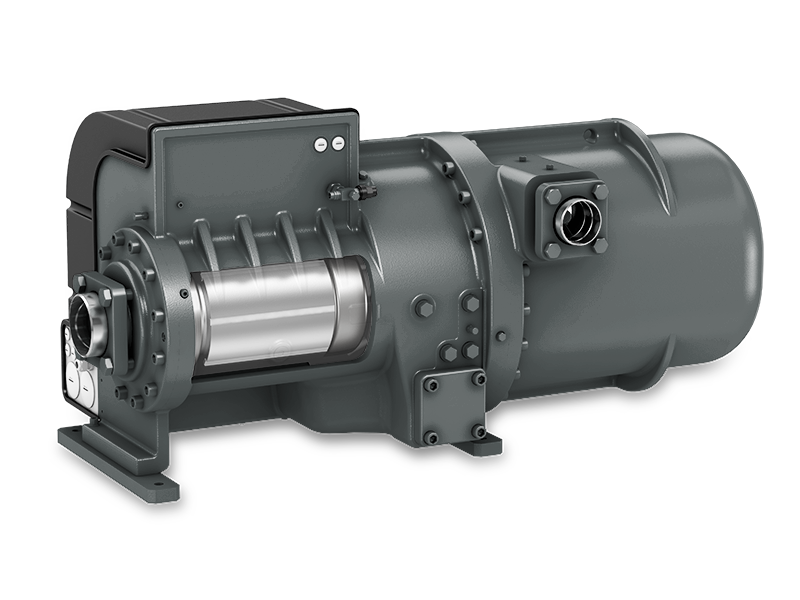

INVERTER-DRIVEN COMPRESSORS

EXACT MATCH TO ACTUAL COOLING LOAD

As cooling capacity and power consumption vary proportionally to the compressor speed, speed control is key to efficient chiller operation. With inbuilt frequency inverters, compressors of Lightstream Screw II Inverter adapt the speed to the actual load, providing maximum energy savings in a wide operating range, precise thermal control, and reduced noise. Ancillary to this, compressors offer integrated functionality: protection, monitoring, data log, and communication in a compact design.

Compressors are designed for use with both traditional and lower GWP refrigerants and optimized for the Ecodesign Directive ambient temperature profile for liquid chillers.

Low vibration levels, service-friendly design, and advanced oil management system with integrated oil separator guarantee a long chiller lifespan without performance degradation.

EFFICIENCY-OPTIMIZED EVAPORATORS

Lightstream Screw II Inverter chillers can be equipped with either shell-and-tube or low-charge falling film evaporators with improved heat transfer characteristics.

SHELL-AND-TUBE EVAPORATOR

Shell-and-tube heat exchangers provide improved thermal performance thanks to optimized flow paths, inner-grooved tubes, and baffles that increase fluid velocity. The net results are closer approach temperature and accurate control of return water temperature – major factors directly related to operating costs and overall chiller efficiency. Evaporators feature overpressure and freezing protection and high-grade insulation.

FALLING FILM EVAPORATOR

Falling film evaporators featuring refrigerant distribution through a spray arrangement above the tube bundle, thus creating a thin film of liquid around the tubes. This type of evaporator permits operation with close approach temperatures between the refrigerant and process fluid and provides high heat transfer coefficients. Falling film evaporators require less refrigerant charge compared to shell-and-tube evaporator designs – without compromising the system’s capacity and energy efficiency.

INTELLIGENT FAN SYSTEM

Condenser fans with impeller geometry enhanced by computational fluid dynamic analysis and controlled by state-of-the-art control software ensure very quiet and efficient operation while drawing less energy – also due to the lowest pressure resistance created by microchannel condenser coils.

Electronically commutated motors with continuous monitoring, less stressed windings and bearings contribute to higher reliability and longer lifespan, while quieter operation results in increased acoustical comfort. Especially at partial loads, Lightstream Screw II Inverter chillers equipped with EC-driven fans represent a significant opportunity to save on operating costs.

MICROCHANNEL CONDENSER COILS

Significant refrigerant charge reduction by up to 50% achieved for Lightstream Screw II Inverter with the use of microchannel condenser coils with multiport tubes having orifices of sub-millimeter diameter, which dramatically decrease the internal volume of the coil.

Brazed joints provide low contact resistance and, in combination with large heat transfer surfaces, enable high heat transfer characteristics for Lightstream Screw II Inverter chillers.

Improved corrosion resistance is another advantage inherent in microchannel coil technology. Heat exchanger components are made of long-life aluminum alloys with a zinc arc spray finish. Additional corrosion protection required for installations in highly polluted zones or coastal applications can be achieved with epoxy electrophoretic or trivalent chromium process coatings available optionally.

- Higher heat transfer rates enable lower condensing temperatures and result in energy savings on compressors

- Low air resistance leads to reduced fan power draw and lowers noise output

- Improved corrosion resistance of all-aluminum condensers increases the service life of the chillers

- Short airflow paths result in less fouling of heat exchangers

- Lower refrigerant charge, up to 50%

CONTROL SOFTWARE

The control solution for chillers with frequency-controlled compressors has been developed around a programmable controller based on a high-speed microprocessor and powerful yet flexible software adopting stepwise capacity control. The software dynamically controls operating limits by continuous reading suction pressure, discharge pressure, and other operating parameters to maintain the chiller’s working point, ensuring maximum chiller protection, reliability, and efficiency.

Giving complete control over the system for the plant operator, the chiller software manages and optimizes the chiller’s performance according to cooling demand and ambient conditions, generates safety and security alarms, supports interlinked, coordinated operation of multiple units, provides diagnostics and run statistics, and allow easy integration with any BMS protocols.

ENVIRONMENTAL SUSTAINABILITY

LOWER GWP REFRIGERANTS

Refrigerants significantly influence the chiller performance and environmental sustainability of the cooling solution. For Lightstream Screw II Inverter chillers, we offer non-ozone-depleting R134a refrigerant, as well as low-GWP refrigerants R1234ze, R450a, and R513a, which make these chillers a true leader in environmental safety – without compromising the performance.

Refrigerant charging amounts are kept to a minimum thanks to microchannel condenser coils with 60% lower internal volume and optimized evaporators.

OPTIONAL FEATURES

Customers may choose from two performance grades, standard and high efficiency with enlarged condensers, and from three noise reduction packages. Special kits for low- or high-ambient operation adapts chillers to environmental conditions existing at the installation site. Lightstream Screw II Inverter chillers can also be factory-fitted with:

- Hydronic kits comprising of single or twin pumps, equipped with variable or fixed-speed drives, bundled with ancillaries

- Free cooling system w/ bypass and regulating valves

- Corrosion protection for condenser coils

- Refrigerant leak detectors

- Control and connectivity options

- Dual power input and redundancy options

- Accessories for servicing

INTEGRATED FREE COOLING

Free cooling version provides low energy cooling and enables significant savings at low-ambient conditions. In mild temperature conditions, when the ambient temperature drops below the return water temperature, the free cooling system operates in parallel with mechanical cooling, maximizing energy savings. Through the use of microchannel cooling coils, the air temperature at which the free cooling system provides 100% cooling demand is higher by 3°C to 5°C compared to heat exchangers of other types. The flow through the cooling coils is controlled through a 3-way mixing valve managed by the chiller software.

PRODUCT SPECIFICATIONS

| Capacity [kW] | 400 … 1700 |

|---|---|

| Design | AIR-COOLED |

| Compressors | VARIABLE-SPEED SCREW |

| Refrigerant | R134A/R450A/R513A/R1234ZE |

| Energy efficiency (EER) | UP TO 3.36 |

| Seasonal efficiency (ESEER) | UP TO 6.43 |

| Fan motors | EC/AC |

| Condensers | MCHE |

| Evaporators | SHELL-AND-TUBE/FALLING FILM |

| Evaporation control | EEV |

| Refrigeration circuits | SINGLE/MULTIPLE |

| Warranty | 3 YEARS |