EFFICIENT COOLING FOR MISSION-CRITICAL ENVIRONMENTS

The Lightstream Freecool is a family of free cooling chillers equipped with frequency-controlled screw compressors and adopted microchannel technology for freecooling and condensing coils, which result in outstanding seasonal energy efficiency in a wide range of workloads and operating conditions.

Lightstream Freecool has been designed with attention to every detail to maximize performance and reliability and perfectly fulfilling requirements of mission-critical applications, industrial, commercial applications, and in every area where efficiency and reliable continuous cooling are the key factors.

Application flexibility is achieved through a wide variety of optional components and accessories and control software with advanced functionality, including coordinated operation under sequence management software.

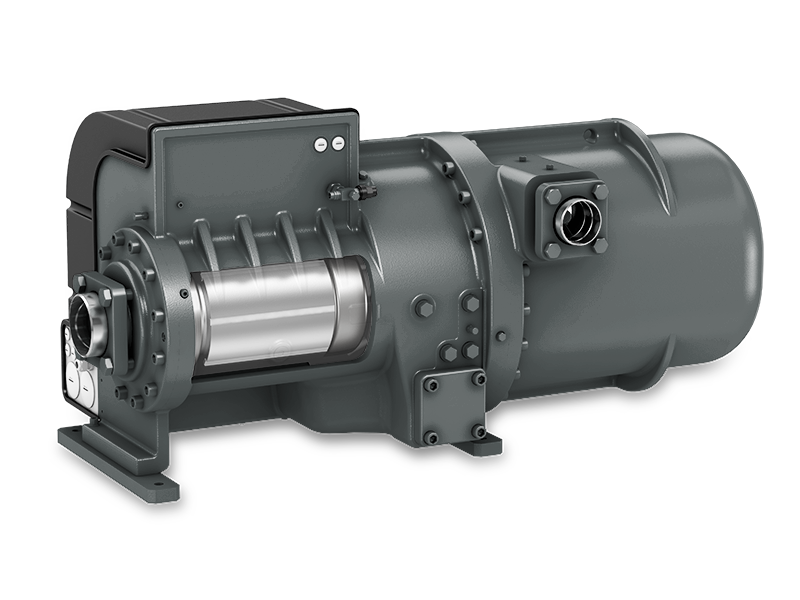

INVERTER SCREW COMPRESSORS

EXACT CAPACITY MATCH AND LARGE REDUCTION IN RUNNING COSTS

Lightstream’s screw compressors with frequency-controlled capacity adjustment are optimized for maximum efficiency in air-cooled chillers. These compressors are especially suitable for systems that frequently operate under part-load and feature an integrated frequency inverter which controls the motor speed – enabling infinite capacity control for customers and optimal energy use in applications.

These compressors achieve impressively high full-load efficiency and significantly improved ESEER/IPLV and SCOP values: with an average ESEER value above 5.5, Lighstream Screw chillers are setting new benchmarks for air-cooled chillers in the industry.

The compressor monitors its own application limits and communicates via Modbus with the master chiller controls. The integrated data log can be used at any time to analyze operation over the running time and optimize the system settings. The integrated soft-start feature facilitates the steady increase of the in-rush current without voltage spikes.

Compressors are also optimized for the temperature profile specified by the Ecodesign Directive for water chillers (European Chiller Energy Efficiency Standard EU 2016/2281 Tier 1, effective from January 2018).

MICROCHANNEL TECHNOLOGY

Microchannel technology adopted in Lighstream Freecool design for both condenser and freecooling coils gives several advantages resulting in a 40% higher heat transfer in comparison to finned tube coil designs.

- Higher heat transfer rates enable lower condensing temperatures and result in energy savings on compressors

- Higher performance of free cooling coils, resulting in improved free cooling opportunities

- Low air resistance leads to reduced fan power consumption and lower noise output

- High corrosion resistance of all-aluminum heat exchanger construction increases the service life of the chillers

- Straight airflow path results in less fouling and clogging of heat exchangers

- Lower refrigerant charge, up to 50%

- Reduced size and weight which translates to lower costs of the system

Optionally available protective coatings enable trouble-free condenser operation in marine atmospheres, high-polluted industrial zones, and other chemically active areas.

LOWER GWP REFRIGERANTS

REFRIGERANTS R513A AND R1234ZE

The portfolio of Lightstream Freecool chillers includes the models that use low-GWP alternatives to R134a. The customers may choose from zero ozone depletion potential refrigerants R1234ze and R513a with the GWP values of less than 1 and 573, respectively.

Recently developed refrigerant R1234ze features low global warming potential and zero ozone depletion potential and fulfills EU regulatory requirements for reducing the use of high global warming potential (GWP) substances. At the same time, R1234ze almost exactly matches the efficiency of R134a. R513a is an azeotropic low-GWP, and non-ozone depleting refrigerant based on hydrofluoro-olefin (HFO), developed to replace R134a. Its energy efficiency and capacity match those for R134a, while its environmental impact significantly reduced.

With low-GWP refrigerants, Lightstream Freecool chiller is the environmentally-friendly leader of the range, while achieving the best energy performance levels for applications.

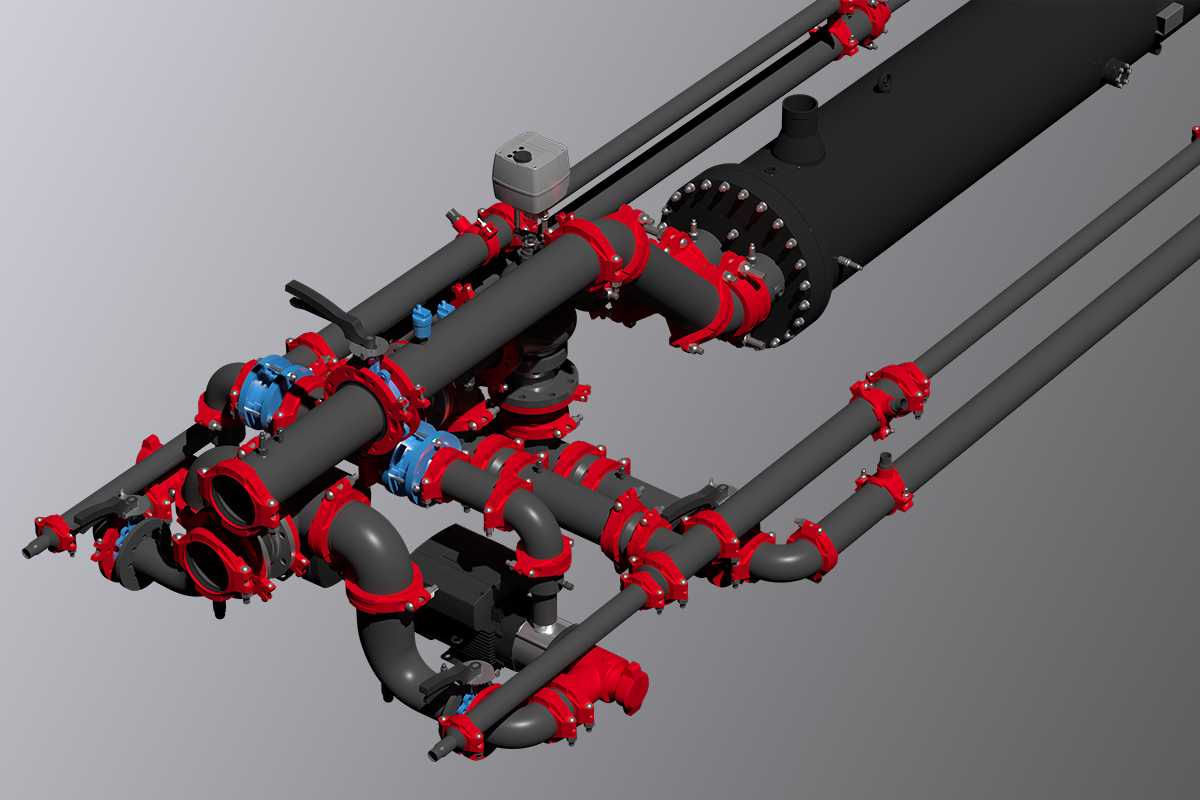

FREE COOLING SYSTEM

The cooling energy consumption takes up a significant portion of the total energy consumption of many applications, such as data centers, commercial and residential buildings, and process cooling. Free cooling is a very effective solution for reducing power consumption of cooling systems: it can take effect when the ambient temperature drops just a degree below the process return water temperature, and this is a major benefit for energy saving.

Lightstream Freecool operates in the mechanical cooling mode when the ambient temperature is high; in the partial free cooling mode when the temperature difference between return water and ambient air is as low as 1°C; and in full free cooling mode when the ambient temperature falls below the return water temperature of about 4°C. Raising the water temperatures when possible will also extend free cooling time.

In mixed and full free cooling modes, the chiller capacity is regulated by mixing valves (either 3-way or 2-way motorized valves) and by reducing fan speed, thus further reducing the power consumption of a chiller. In addition, the variable speed control of the fans allows the load to be precisely matched to cooling duty. The transition between the cooling modes is assured by the chiller control system which constantly measures the outdoor temperature.

When the chilled water plant comprises several free cooling chillers, the sequence management system can be used to achieve optimal energy efficiency.

In contrast to convenient air-cooled chillers, free cooling chillers have expanded operating scope and can function at very low ambient temperature conditions.

20% Higher Efficiency

Higher microchannel condenser performance results in a reduced condensing temperature, which in turn reduces compressor power consumption and increases the overall chiller efficiency, while the permissible operating scope of the compressors is increased to a higher ambient temperature.

The superior performance of the microchannel freecooling coil translates to higher free cooling capacity and increased free cooling hours, thus improving the overall system efficiency. At the same time, the microchannel freecooling coils do not affect the fan power consumption due to the low airside pressure drop.

INTELLIGENT FAN SYSTEM

EC-DRIVEN FANS WITH REDUCED POWER CONSUMPTION

Smart fan system specially developed for Lightstream Freecool chillers not only reduces power consumption by up to 30% while efficiently managing high volume flows – but it also works at much reduced operating noise. The smart fan system includes the unique fan impellers with bionic wing concept, the most advanced EC-motor technology, and multifunctional air diffusers, resulting in an extra efficiency for the customers.

EC-motors use commutation electronics to sense the rotor position and adjust supply current, thus eliminating the need for mechanical brushes to deliver current to the motor windings. Elimination of physical contact reduces internal wear within the fan motor and significantly increases reliability.

EC-motor technology provides savings during full-load operation, as well as under partial loads when EC motors lose much less of their efficiency compared to AC fans.

PRODUCT SPECIFICATIONS

| Capacity [kW] | 450 … 1200 |

|---|---|

| Design | FREE COOLING |

| Compressors | SCREW |

| Refrigerant | R134A/R513A/R1234ZE |

| Energy efficiency (EER) | UP TO 4.10 |

| Seasonal efficiency (ESEER) | UP TO 5.95 |

| Fan motors | EC |

| Condensers | MCHE |

| Free cooling coils | MCHE |

| Evaporators | FLOODED S&T |

| Evaporation control | EEV |

| Refrigeration circuits | DOUBLE |

| Warranty | 3 YEARS |