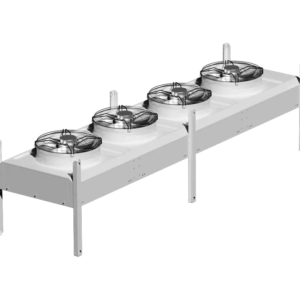

HIGH-END, DEMAND-RESPONSIVE CONDENSERS FOR MISSION-CRITICAL APPLICATIONS

Designed and optimized for a vast majority of refrigerants, including R410a, R134a, R1234ze and more, LCC series modular air-cooled condensers are equipped with brazed aluminium heat exchangers and electronically commutated (EC) fans. A wide range of options and accessories available for tailoring the customer solution, including adiabatic spray system, e-coating for condenser coil protection, automatic coil cleaning system, and BMS connectivity options.

The LCC range is built as V-shaped condenser modules to minimize the footprint. Its modular construction allows each V-bank to be connected independently offering autonomous regulation.

Electronically-Commutated Axial Fans

Axial fans driven by EC-motors have high energy-saving potential in particular, under part-load, where efficiency losses are significantly lower than those for fans with asynchronous motors. In combination with low air-resistant coils, EC fans promote significant energy savings while remaining relatively quiet over the entire speed range. To fulfill the most demanding noise requirements, fans can be fitted with advanced diffusers.

Microchannel Condensing Coils

Microchannel heat exchangers with vertical tube arrangement are beneficial for improving the condenser performance, especially at part-load conditions:

- 40% higher heat transfer efficiency compared to fin/tube designs

- Low airside pressure drops

- Closer approach temperatures

- Up to 20% smaller coil face

- Less weight (up to 50%)

- Less refrigerant charge (typically 40% to 60%)

PRODUCT SPECIFICATIONS

| Capacity [kW] | 100 … 800 |

|---|---|

| Fan quantity | 2 … 8 |

| Fan motors | EC |

| Low-ambient kit | AVAILABLE |

| Low-noise models | AVAILABLE |

| Heat exchangers | MCHE |

| Protective coatings | E-COATING/TCP-COATING |

| Refrigerants | HFC/HFO |

| Warranty | 3 YEARS |