POWERFUL SOLUTION FOR DATA CENTER COOLING

With the rapid development of cloud computing and mobile internet, the growth of computing power and energy consumption significantly increases the heat load density in data centers, and this trend will be observed in the foreseeable future.

Today’s data centers require effective cooling systems in order to function while allowing for growth, and Lambda In-Row CW II is the solution. Based on modern, advanced cooling technologies, it offers high cooling density, improved power usage effectiveness (PUE), saves data center space, and simplifies its infrastructure.

WHY LAMBDA?

Save data center space, reduce initial and operating expenses, simplify data center infrastructure

Precise Air Distribution

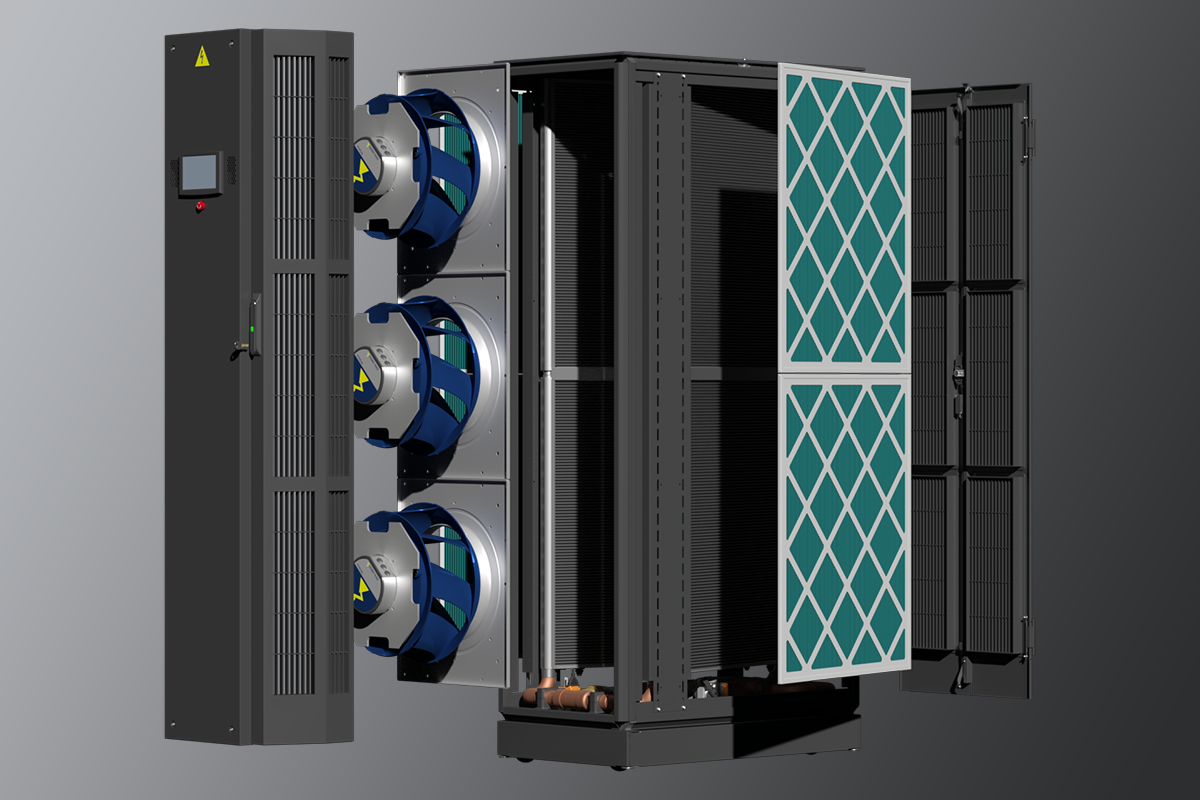

Lambda In-Row CW II ensures optimum air distribution across rack installations thanks to the air management system with individually regulated airfoil baffles incorporated in the front door. It moves air volumes large enough to serve more server cabinets and distribute cooled air evenly between them.

High Cooling Density

Lambda In-Row CW II offers an exceptionally high capacity and cooling density of 180kW/m². This translates to less cooling units, simplified chilled water pipework, streamlines power distribution network, thus substantially lowering installation investments and maintenance costs for the data center infrastructure.

Space-Saving

Datacenter space is highly expensive, and every centimeter counts. With a high-capacity Lambda In-Row II system, customers can reduce the number of installed cooling units by more than fourfold compared to the range of similar solutions, freeing additional space for server racks.

MICROCHANNEL EVAPORATORS

Lambda In-Row CW II features microchannel cooling coils with a remarkably high heat transfer performance and quite low air resistance.

Microchannel tubes brazed together with louvered fins using a controlled atmosphere brazing furnace have a perfect and permanent contact between tubes and fins, assuring an efficient heat transfer. The small hydraulic diameter of the microchannel tubes and high efficiency of louvered fins further improves the heat transfer performance. The flat geometry of microchannel tubes results in reduced aerodynamic drag while minimizing the air shadow on the back side of the tube. The end effect is the reduced airside pressure drop and lower required fan power.

Aluminium microchannel coils are lightweight, robust and have significantly lower internal volume, resulting in lower unit weight and simplified design.

DESIGN AND ASSEMBLY

Lambda In-Row CW II design based on the latest HVAC technologies and advanced control software to maximize its efficiency, reliable operation, and application flexibility:

- Unit controls with large touchscreen display and user-friendly interface

- Cooling coils

- Air distribution system with regulated baffles

- Latest generation centrifugal fans with EC-motors

- Air filtration

- Water circuit

FEATURES AND FUNCTIONALITY

Rack Monitoring

The cooling unit continually monitors thermal parameters of up to 16 racks by reading from temperature sensors installed on air inlets and outlets. When the temperature inside the controlled server racks rises above the set point, the control system issues an alert via the local area network to which the cooling unit is connected, as well as via Android-based software for remote control.

Dewpoint Control

The control system continuously monitors inlet air temperature and humidity to minimize condensate build-up by regulating water flow through the evaporator coils. The system eliminates the possibility of condensate spills through dewpoint control and automatic condensate discharge system equipped with the drain pans, water sensor, and pump.

Networked Operation

Local area network (LAN) can be used to connect up to 16 Lambda In-Row CW II units for synchronized operation and run/standby control. With the networked operation, various scenarios can be deployed depending on operational requirements, including unit rotation, load distribution, energy use minimization, etc.

Free Cooling Operation

When coupled to a chilled water system with a free cooling circuit, Lambda In-Row CW II units able to run up to 98% of the time in free cooling mode, thus saving a significant amount of energy.

In data center applications, the cooling air temperature can be elevated to 27°C without any negative impacts on electronic equipment. In connection with the increase in air temperature, the chilled water temperature can also be increased, thus generating additional free cooling opportunities.

HOT-SWAPPABLE FANS

For cooling equipment used in mission-critical or 24/7 environments, redundant and hot-swap, components are essential. Our in-row units feature hot-swap fan assemblies that facilitate the fan replacement on running units without disrupting the service. When the fan goes offline, the remaining fans will compensate for the lack of airflow by increasing the rotation speed.

PRODUCT SPECIFICATIONS

| Capacity [kW] | 140 |

|---|---|

| Cooling source | CHILLED WATER |

| Energy efficiency (EER) | 41.3 |

| Fan motors | EC |

| Heat exchangers | MCHE |

| Cooling circuits | SINGLE |

| Dew point control | AVAILABLE |

| BMS connectivity | AVAILABLE |

| Warranty | 3 YEARS |