PRECISION COOLING SYSTEM FOR DATA CENTER APPLICATIONS

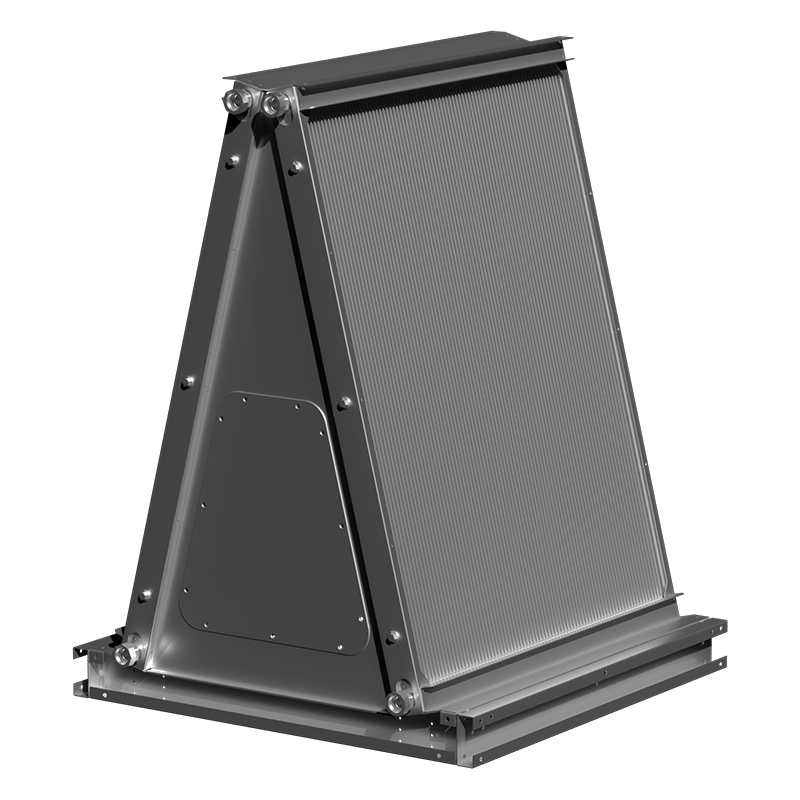

Lambda CW II-M precision air conditioning system takes advantage of chilled water as a source for cooling IT equipment in small and medium-sized data centers. This flexible, cost-efficient solution offers high redundancy, tolerance to faults, and energy-efficient cooling.

The modular nature of the Lambda CW II-M system enables easy and cost-effective expansion in line with the growth of cooling demand. Initial system configuration includes one or two – for system redundancy – active modules to control thermal parameters of the cooled space, while passive modules can be added as necessary – even without interruption in cooling.

Space-saving design provides the highest performance-to-footprint ratio for applications and easy servicing with frontal access to all system components. Numerous optionals and control functions are available for tailoring the system to individual requirements.

MICROCHANNEL HEAT EXCHANGERS

Lambda CW II-M features close-approach microchannel cooling coils that substantially improve heat transfer performance due to small-diameter tube ports and brazed joints. The coil performance enhanced on both air- and fluid-side, offering low airside fin resistance and consequently lower fan energy consumption and noise, and small coil internal volume.

Heat transfer improvements permit increased energy efficiency of Lambda CW II-M air conditioners, reduced operating noise, and reduced unit weight. Low fluid-side coil pressure drops also enable savings on pump power.

Microchannel cooling coils feature a zinc-treated internal surface for high corrosion resistance to use in applications with high/low water pH values, non-treated water, and without inhibitors.

HIGHER ENERGY EFFICIENCY

LOWER UNIT WEIGHT

INTELLIGENT FANS

Lambda CW II-M system features backward-curved radial fans with unique blade geometry offering increased airflow by smaller impeller size, wider efficiency range, and low sound output. Fan drives use commutation electronics to sense the rotor position and adjust supply current, thus eliminating the need for mechanical brushes to deliver current to the motor windings. Elimination of physical contact reduces internal wear within the fan motor and significantly increases reliability.

The key advantage of using EC-driven fans is substantial energy savings – of up to 35%. Furthermore, electronically-commutated motors feature overtemperature protection, are maintenance-free and have an extended lifetime in comparison to any other motor types.

The fans fully comply with the requirements of the Energy-related Products 2015 Directive.

ADVANCED CONTROLS

The control hub of Lambda CW II-M is a sophisticated microprocessor with control logic specially developed for chilled water air conditioners. Extended functionality provides full unit management either locally or remotely, enables energy use optimization, and allows configuring multiple units simultaneously by replicating the configuration and parameters onto a group of networked units. Users can apply various control strategies based on either constant temperature control, or on-demand airflow control, or constant pressure control by maintaining a pressure differential between the cold and hot aisles.

FLOW REGULATION

Lambda’s water circuit equipped with smart balancing system based on continuous pressure drop measurements on return and bypass lines. Depending on these measurements, the unit control system adjusts two-way valves and maintains necessary cooling media flow through the cooling coils, thus avoiding manual fluid circuit balancing. Automatic balancing system fits ideally with variable-flow chilled water systems. Fluid circuit with a 3-way regulating valve for constant flow chilled water systems available as an option.

PRODUCT SPECIFICATIONS

| Capacity [kW] | 55 … 335 |

|---|---|

| Cooling source | CHILLED WATER |

| Energy efficiency (EER) | UP TO 51.1 |

| Fan motors | EC |

| Heat exchangers | MCHE |

| Cooling circuits | SINGLE |

| Humidity control | AVAILABLE |

| BMS connectivity | AVAILABLE |

| Warranty | 3 YEARS |