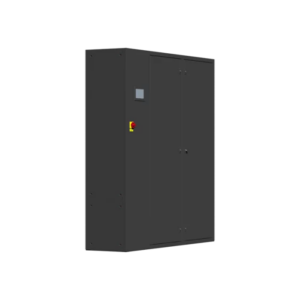

PRECISION COOLING UNITS PERFECT IN PERFORMANCE AND TECHNOLOGY

Designed especially for mission-critical applications, Lambda CW/CWU precision air conditioning system provides accurate thermal and humidity control and air filtration. Sophisticated controls enable creating precision cooling solutions with increased focus either on energy efficiency, higher performance, or combination of both, giving customers the flexibility to design efficient, tailor-made solutions, matching increasingly complex requirements as closely as possible.

Lambda range includes three performance grades with a wide range of redundancy options and management features, thus permitting tailor-made cooling solutions suitable for applications such as data centers, telecommunication facilities, clean rooms, production sites, process plants. The units are available with integrated or underfloor fan compartments.

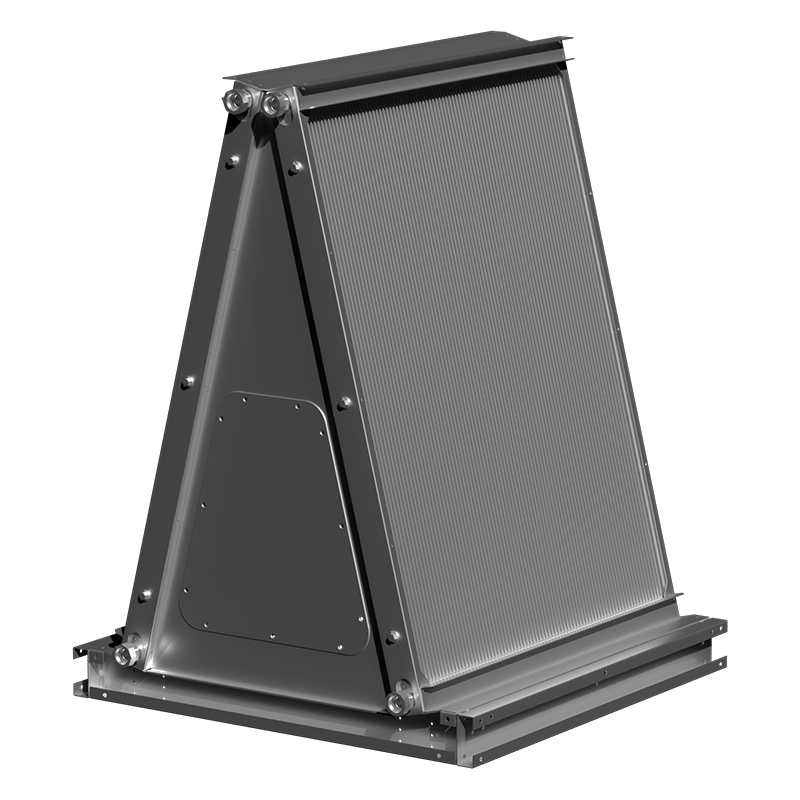

MICROCHANNEL HEAT EXCHANGERS

Lambda units based on newly developed all-aluminium microchannel heat exchangers with an advanced design that combines high-performance flat tubes, state-of-the-art airside fins, and ultra low-pressure drop headers. The tubes have numerous miniports that enhance fluidside performance, while the airside achieves closer approach temperatures and, in combination with doubled area A-shaped heat exchanger design, reduces airside pressure drops drastically.

The end result is incredibly low fan power consumption and, consequently, high energy efficiency: the maximum EER is 84.2, while the lineup’s average EER is 59.6 (for 7/12°C water). Compared to old-style fin/tube designs, microchannel heat exchangers helps to achieve up to 40% higher efficiency, reduce weight by approx. 50% and use less coolant volume.

HIGHER ENERGY EFFICIENCY

LOWER UNIT WEIGHT

ADVANCED EC FANS

Lambda CW/CWU features the backward-curved radial fans with unique blade geometry and offers increased airflow by smaller impeller size, wider efficiency range, and low sound output. EC motors use commutation electronics to sense the rotor position and adjust supply current, thus eliminating the need for mechanical brushes to deliver current to the motor windings. Elimination of physical contact reduces internal wear within the fan motor and significantly increases reliability. Electronically commutated motors feature overtemperature protection and are maintenance-free and have a longer lifetime in comparison to any other type of motors. The fans also demonstrate full compliance with the requirements of Energy-related Products (ErP) 2015 Directive.

The range includes Lambda CW models with an easily accessible integrated fan compartment and additional noise insulation, making these units one of the quietest precision air conditioners on the market. Lambda CWU models feature an underfloor fan compartment with free radial air distribution, which further improves fan efficiency.

CHILLED WATER CIRCUIT

Lambda’s fluid circuit equipped with smart balancing system based on continuous pressure drop measurements on return and bypass lines. Depending on these measurements, the unit control system adjusts two-way valves and maintains necessary cooling media flow through the cooling coils, thus avoiding manual fluid circuit balancing. Automatic balancing system fits ideally with variable-flow chilled water systems. Fluid circuit with a 3-way regulating valve for constant flow chilled water systems available as an option.

FRAME AND ASSEMBLY

Extensive use of aluminuim components in Lambda CW/CWU design makes its construction lightweight, yet durable. Special attention has been paid to Lambda’s enclosure airtightness to prevent leaks and maximize airside efficiency.

The unit enclosure has been engineered with emphasis on specific data center infrastructure requirements, and as a result, Lambda CW/CWU units can be easily integrated into the data center whitespace. Detachable facing panels allows easy and quick access to internal components of the units for check and maintenance procedures.

PRODUCT SPECIFICATIONS

| Capacity [kW] | 40 … 135 |

|---|---|

| Cooling source | CHILLED WATER |

| Energy efficiency (EER) | UP TO 84.2 |

| Fan motors | EC |

| Heat exchangers | MCHE |

| Cooling circuits | SINGLE/DOUBLE |

| Humidity control | AVAILABLE |

| BMS connectivity | AVAILABLE |

| Warranty | 3 YEARS |