HYBRID EVAPORATIVE DRY COOLERS

Jumbo Cooler is a dry cooler featuring all the benefits of evaporative cooling, developed to operate effectively in conditions where the required water temperature approaches the ambient dry bulb temperature. The system is well adapted for variable cooling loads, as well as for operating across a wide range of environmental conditions.

Equipped with E•VAP™, evaporative pre-cooling sections combined in series with microchannel heat exchangers, Jumbo Cooler offers increased cooling capacity, efficient cooling even at hot ambient conditions, minimum water usage, and increased economization hours in free cooling applications.

With all-aluminum, water-retaining evaporative media and automatic heat exchanger cleaning, Jumbo Cooler requires minimum maintenance during its life cycle – which results in a significant reduction of the total cost of ownership.

Evaporative Pre-Cooling

BOOSTS SYSTEM EFFICIENCY UP TO 30%

EXTENDS OPERATING LIMITS

E•VAP™ evaporative pre-cooling system cools ambient air before it enters the heat exchangers. Even in humid environments, Jumbo Coolers offer remarkable performance and expand the scope of operation of the cooling system. Equipping Jumbo with evaporative pads results in significant energy savings of up to 30%.

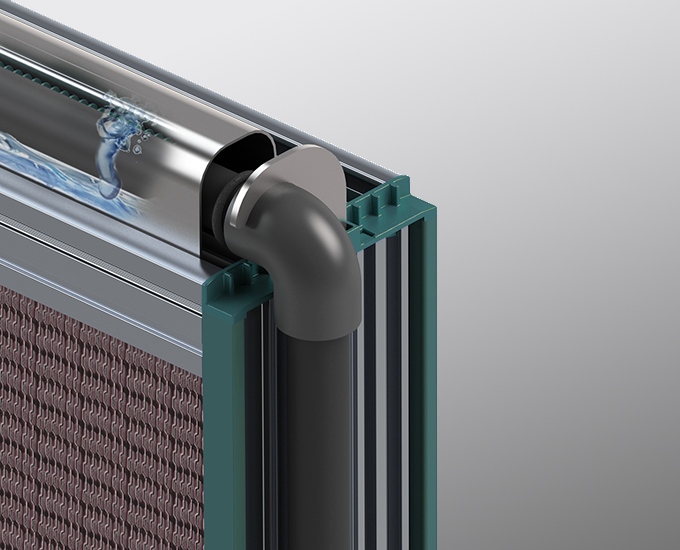

The evaporative media of E•VAP™ is based on water retaining finned aluminium plates designed for maximum evaporation: saturation efficiency reaches 90% and more at air velocities up to 2m/s. The internal geometry and special fin coating of evaporative media facilitate cleanliness of the evaporative media during the operation.

In order to achieve maximum efficiency and minimal water usage, E•VAP™ pre-cooling system can be equipped with a pumping station which includes circulation pump, water treatment module and control system with state-of-the-art algorithms that monitor the ambient conditions and determine operation modes, ensuring the E•VAP™ system is active only when necessary. The fully automated water management system continuously monitors water quality, drains the system and refreshes the water when mineral levels reach certain values.

Evaporative pads can be easily detached for maintenance and access to the heat exchangers for cleaning.

Large-Surface Cooling Coils

ENHANCED HEAT TRANSFER

SUBSTANTIAL CORROSION PROTECTION

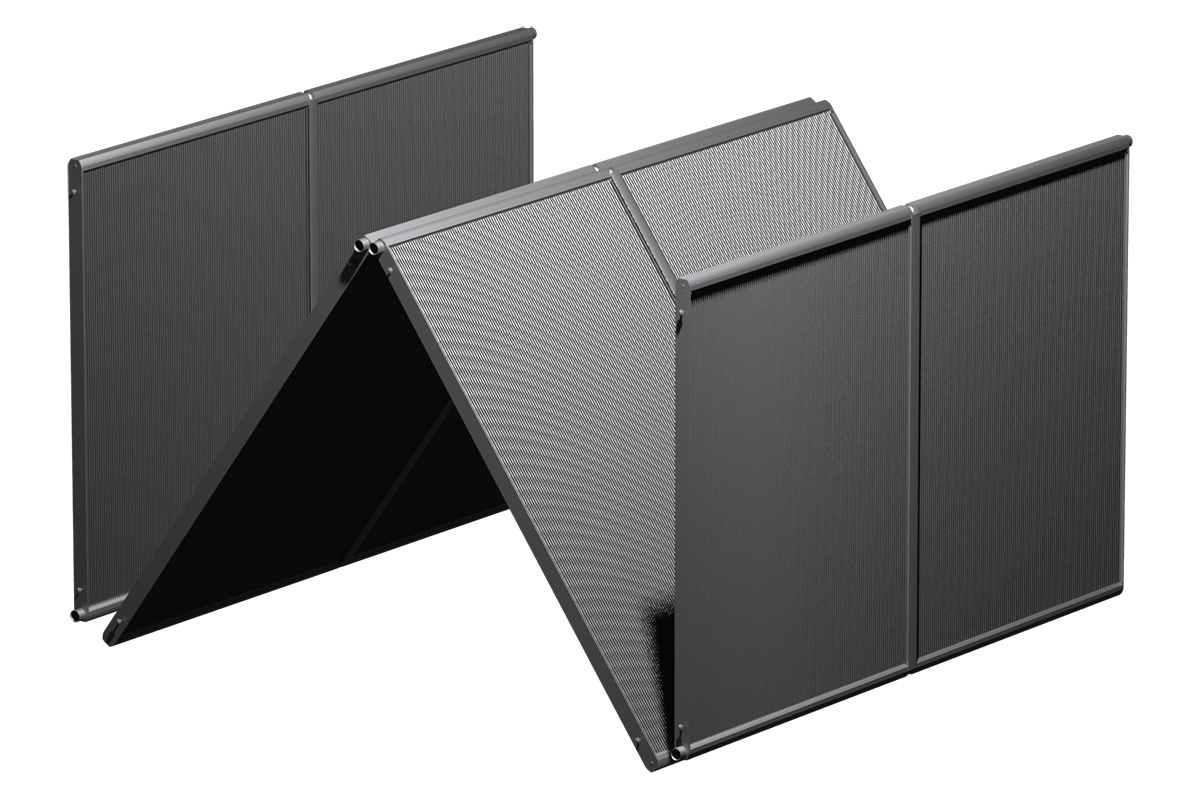

MODULAR W-BANK DESIGN

Microchannel technology provides Jumbo hybrid coolers with numerous benefits, including higher heat transfer rate, decreased fan power consumption thanks to lower airside pressure drops, closer approach temperatures, smaller unit footprint, and reduced weight. The synergy effect is unrivalled performance and efficiency, lower system cost and reduced operating expenses.

High corrosion resistance enables the long lifetime of Jumbo Coolers in the seashore, aggressive, and chemically polluted atmospheres.

Depending on the customer requirements, Jumbo Cooler heat exchangers can be combined in a single or dual circuit.

Free Cooling Applications

EXTENDED ECONOMIZATION HOURS

Jumbo Cooler is indispensable for high energy efficient free cooling applications and excellent solution to work in conjunction with water-cooled chillers.

With Jumbo, which cools down the air to temperatures at 1ºC to 2ºC above wet bulb temperature before it enters heat exchangers, economizations hours can be extended dramatically, thus reducing mechanical cooling hours and saving a large amount of energy. Moreover, substantial depression of the dry bulb air temperature results in a major increase in cooling capacity.

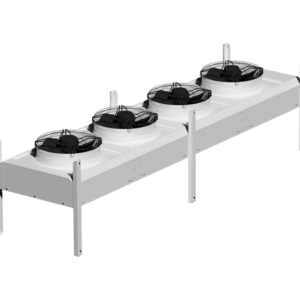

Axial Fans

EFFICIENT, QUIET AND COST-EFFECTIVE EC-FANS

Axial fans used in Jumbo design have outstanding characteristics in every respect, including performance and efficiency, weight, noise pollutions, and robustness.

EC technology is one of the key foundations of energy efficiency, and we equip Jumbo hybrid coolers with the latest EC motors which demonstrate impressive performance, low energy consumption, high torque, and durable design.

Comprehensive corrosion protection measures have been taken that allow the fans to be used in almost all climatic applications with outstanding operating reliability.

Array of Options

We offer a huge selection of options and accessories for Jumbo Cooler to make it flexible and suitable for all the possible applications:

- Single or double water circuit

- Automatic coil cleaning system

- Coil coatings for maximum corrosion protection in coastal applications

- Single or dual inline pumps, including those with inverter technology

- Water storage tanks

PRODUCT SPECIFICATIONS

| Capacity [kW] | 200 … 1600 |

|---|---|

| Fan quantity | 4 … 24 |

| Fan motors | EC |

| Automatic coil cleaning | AVAILABLE |

| Cooling circuits | SINGLE/DOUBLE |

| Heat exchangers | MCHE |

| Protective coatings | E-COATING/TCP-COATING |

| Refrigerants | WATER/BRINE |

| Warranty | 3 YEARS |