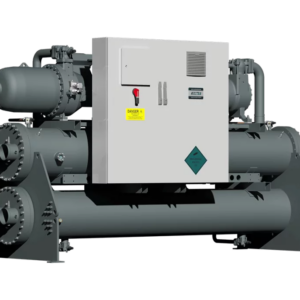

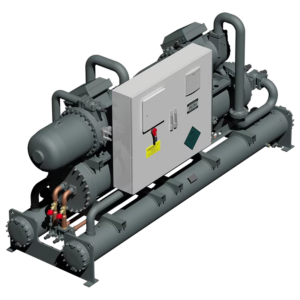

EXACT CAPACITY MATCH, SHORT PAYBACK PERIODS

Through a combination of efficiency-enhancing technologies, including direct-current inverter scrolls, Easystream II Inverter delivers efficiency levels beyond typical of chillers in its class and exceeds stringent regulatory requirements while running smoothly and quietly.

Easystream II Inverter series chillers operate efficiently across all cooling loads and working conditions versus fixed-speed chillers with stepped unloading designs.

Thanks to the more reactive adaptation to cooling demand, these chillers contribute to lower installation costs, e.g., by downsizing or eliminating buffer water tanks, reduction in footprint, etc. The chillers offer lower sound levels compared to systems with on-off compressors, especially under part-load conditions, at night time – in both operating and startup time.

INVERTER SCROLL COMPRESSORS

PERFECT PART-LOAD AND SEASONAL EFFICIENCIES

Inverter scroll compressors offer variable speed technology – the best way to comply with today’s energy standards with high part-load and seasonal efficiencies while providing several other benefits like precise cooling and humidity management, low startup current, low acoustic level, and wider operating map to cover most commercial applications in air conditioning.

Easystream II’s scroll compressors feature IDV (Intermediate Discharge Valve) valves and permanent magnet motors that are the major contributors to its highest performance levels.

Configurations available for Easystream II Inverter chillers include single inverter-driven compressors, manifolded inverter plus fixed-speed compressors, and inverter-driven compressor tandems.

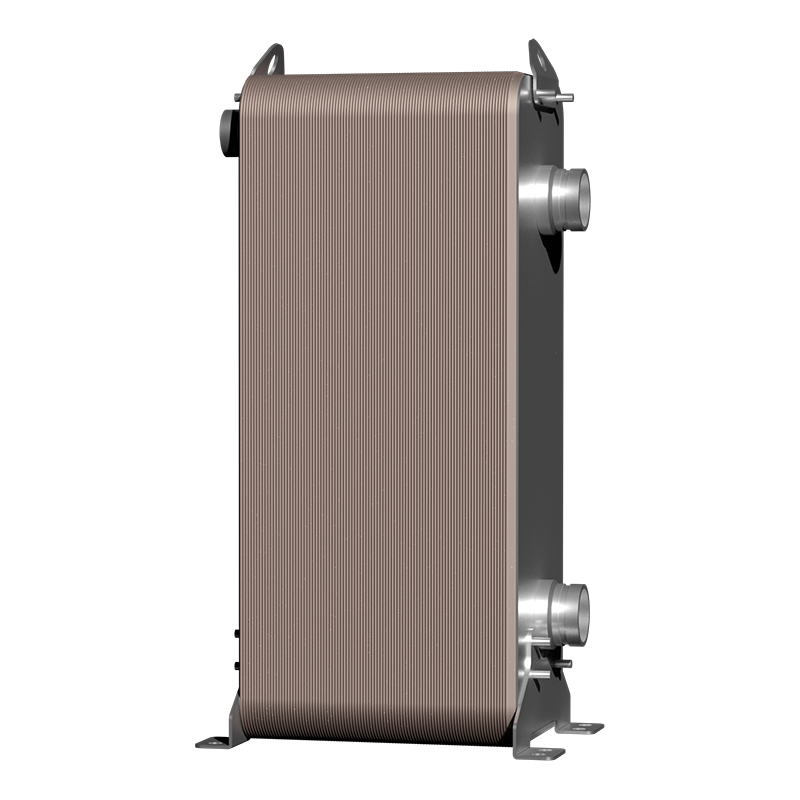

EVAPORATORS

BRAZED PLATE HEAT EXCHANGERS

Incorporating a brazed plate evaporator with improved plate geometry and optimized flow paths offers certain advantages. The most important of these are minimal approach temperature and reduced pressure losses.

A closer temperature approach enables higher evaporation temperature, thereby promoting improved compressor’s coefficient of performance (COP) and less energy use. With the reduction of pressure losses, required pump energy decreases, giving the customers a perfect opportunity for further savings.

The special design of evaporator plates guarantees consistent joints at the plate overlaps and assures leak-proof construction. Advanced plate geometry also ensures better metallurgical bonding, leading to optimal heat transfer efficiency.

FEATURES AND OPTIONS

PRODUCT SPECIFICATIONS

| Capacity [kW] | 40 … 350 |

|---|---|

| Design | WATER-COOLED/CONDENSERLESS |

| Compressors | SCROLL |

| Refrigerant | R410A |

| Energy efficiency (EER) | UP TO 5.76 |

| Seasonal efficiency (ESEER) | UP TO 7.06 |

| Condensers | BPHE |

| Evaporators | BPHE |

| Evaporation control | EEV |

| Refrigeration circuits | SINGLE/MULTIPLE |

| Warranty | 3 YEARS |