DESIGNED FOR HIGH-DEMAND COOLING APPLICATIONS

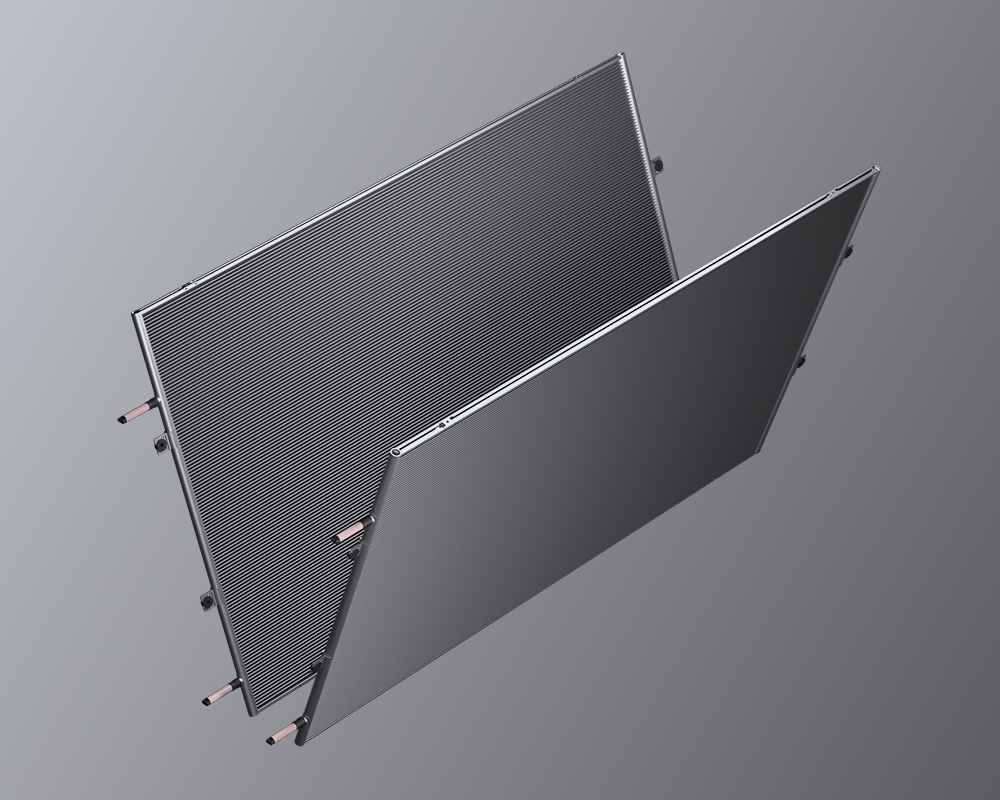

The idea behind Bora XL design is the synergy of high availability demanded by mission-critical cooling applications and extensive configurability deriving from its modular construction. In parallel, Bora XL offers savings on energy, water, and remarkable corrosion resistance through the use of all-aluminum heat exchangers.

These dry coolers are perfect for use with demand-responsive chillers with water-cooled condensers or as a stand-alone free cooling system, ensuring the optimum operating performance for the cooling plant. While being compact, lightweight and low-noise, the solution also suitable for use in commercial buildings and installations in urban areas.

Bora XL can be configured with integrated circulation pumps for constant or variable flow, multiple cooling circuits, fan speed controllers, adiabatic cooling, and several other accessories to meet specific application needs.

Features And Advantages

DESIGN ADVANTAGES, FLEXIBILITY & COST BENEFITS

- Low power consumption, water-saving design, low carbon footprint

- Optimized for partial-load operation

- Comprehensive lineup in 10 frame sizes

- Integrated optionals, including pumps, multi-circuiting, adiabatic cooling

- Corrosion-resistant heat exchangers

- BMS integration

- Low-maintenance solution

- Long service life

High Performance, Excellent Protection Against Corrosion

High heat transfer performance, lower fans power draw, close temperature approach, reduced weight – are advantages provided by microchannel coil technology incorporated in the Bora XL design.

All-aluminum heat exchanger construction made from long-life alloys developed especially for HVAC applications ensures excellent anti-corrosive properties. Additional protection can be provided with epoxy electrophoretic heat exchanger coating (available optionally). Special chemical treatment of the inner coil surface allows extending the safe pH range of the working fluid, contributing to the high corrosion resistance of heat exchangers.

Lower cost and less time required for maintenance are other significant benefits of microchannel heat exchanger technology available for Bora XL customers.

EC Fans For Optimized Airflow Control

As demand-responsive HVAC equipment often operates in partial-load conditions, the use of EC fans leads to considerable savings on energy consumption – up to 50% compared to AC motors.

As standard, Bora XL dry coolers are equipped with EC-motor axial fans with Modbus control. These last-generation fans distinguish by optimized energy consumption and low operating noise.

EC-motors used in Bora XL design offer an extended range of operating temperatures and have integrated overheat protection. Fan rotation speed can be managed by an external signal or by an in-build controller.

PRODUCT SPECIFICATIONS

| Capacity [kW] | 100 … 1500 |

|---|---|

| Fan quantity | 1 … 20 |

| Fan motors | EC(STANDARD)/AC |

| Cooling circuits | SINGLE/MULTIPLE |

| Adiabatic spray system | AVAILABLE |

| Low-noise models | AVAILABLE |

| Heat exchangers | MCHE |

| Protective coatings | E-COATING/TCP-COATING |

| Refrigerants | WATER/GLYCOL |

| Warranty | 3 YEARS |