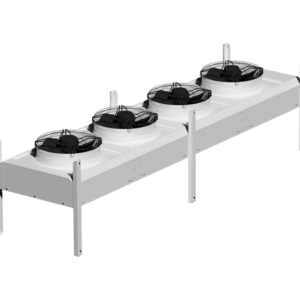

LEADING EDGE DRY COOLERS

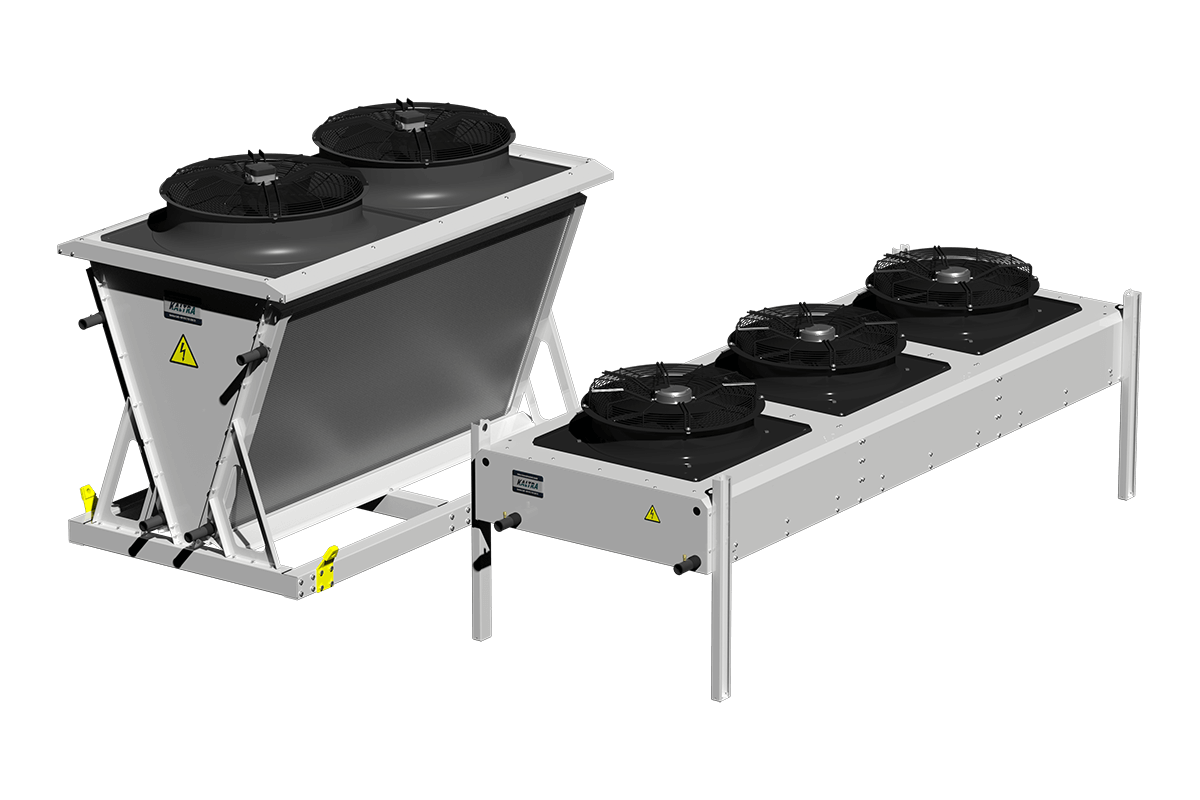

Bora dry cooler is a concentration of new heat transfer and HVAC technologies, including microchannel technology, evaporative cooling, and modern EC-driven fans. Bora dry coolers cover the application range up to 2MW, suitable for commercial, air conditioning, and industrial process applications.

The optional evaporative pre-cooling system offers substantial energy savings, increased capacity, and reduced noise emissions, and enables the use of Bora dry coolers at extremely high ambient temperature conditions without efficiency loss.

The range includes a large number of models to select from: with V-shaped or horizontal microchannel heat exchangers, units with V-shaped or heavy-duty vertical evaporative pads, equipped with EC- or AC-motor fans and single or double water circuits, in standard or low noise configurations.

PERFORMANCE AND BENEFITS

Bora Standard Dry Coolers

PERFORMANCE & EFFICIENCY

- Unrivalled heat transfer performance

- Enlarged operating envelope

ENVIRONMENTAL & COST

- Superior corrosion resistance

- Low noise emission

- Reduced footprint

- Low overall TCO

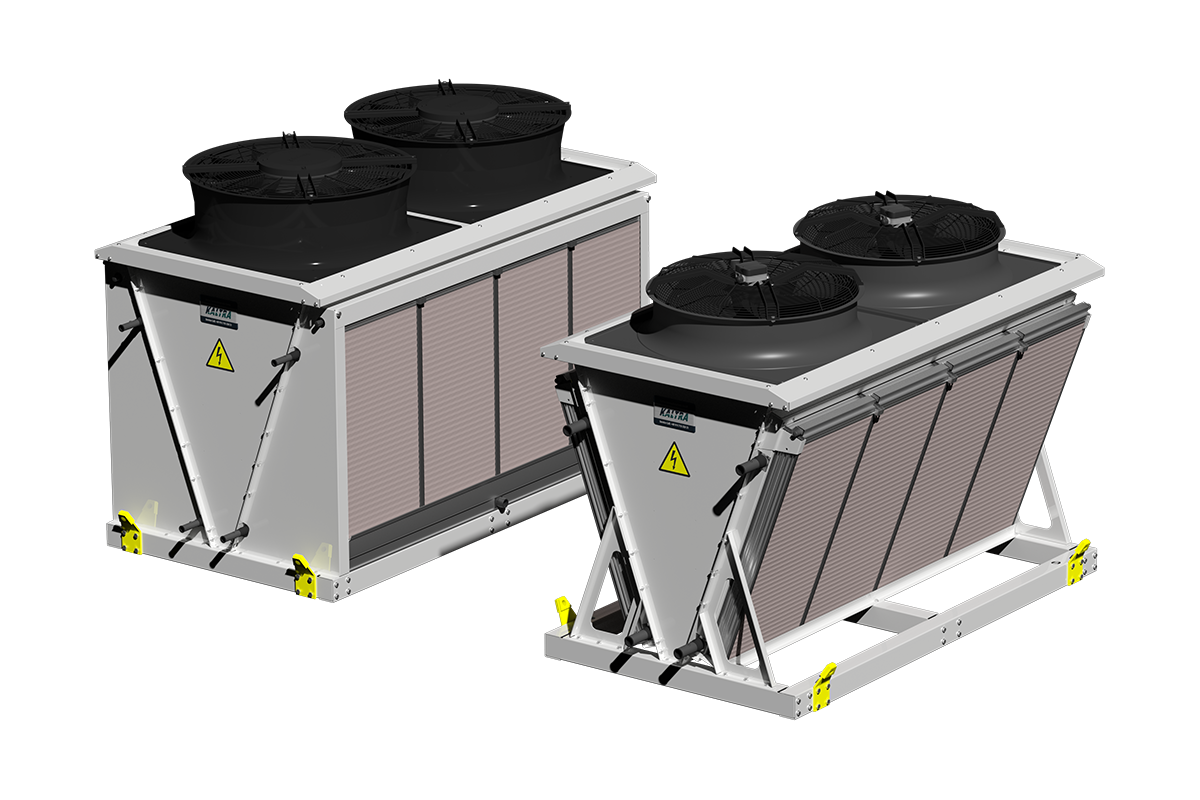

Bora Dry Coolers With Evaporative Pre-Cooling

PERFORMANCE & EFFICIENCY

- Enlarged operating envelope for hot climates

- Unprecedented 30% energy savings on compressors

- Reduced compressor peak loads

- Increased heat rejection

ENVIRONMENTAL & COST

- Reduced fan speed and associated noise emission

- No bacterial growth on evaporative media

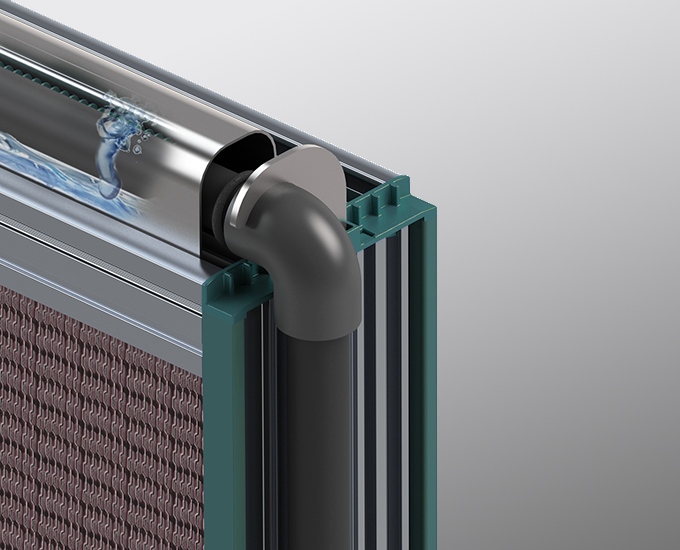

Evaporative Pre-Cooling

BOOSTS SYSTEM EFFICIENCY UP TO 30%

REDUCES COMPRESSOR WORK

Evaporative pre-cooling system provides cooling of ambient air before entering the heat exchangers. Even in humid environments, Bora dry coolers offer remarkable performance and expand the scope of operation of the cooling system. Equipping Bora dry coolers with evaporative pads results in significant energy savings of up to 30%.

The evaporative media of E•VAP™ based on water retaining finned aluminium plates designed for maximum evaporation: saturation efficiency reaches 90% and more at air velocities up to 2m/s. The internal geometry and special fin coating of evaporative media facilitate cleanliness of the evaporative media during the operation.

In order to achieve maximum efficiency and minimal water usage, the E•VAP™ pre-cooling system can be equipped with a pumping station which includes circulation pump, water treatment module, and control system with state-of-the-art algorithms that monitor ambient conditions and determine operation modes, ensuring the E•VAP™ system is only active when necessary. The fully automated water management system continuously monitors the water quality, drains the system and refreshes the water when mineral levels reach certain values.

Evaporative pads can be easily detached for maintenance and access to the heat exchangers for cleaning.

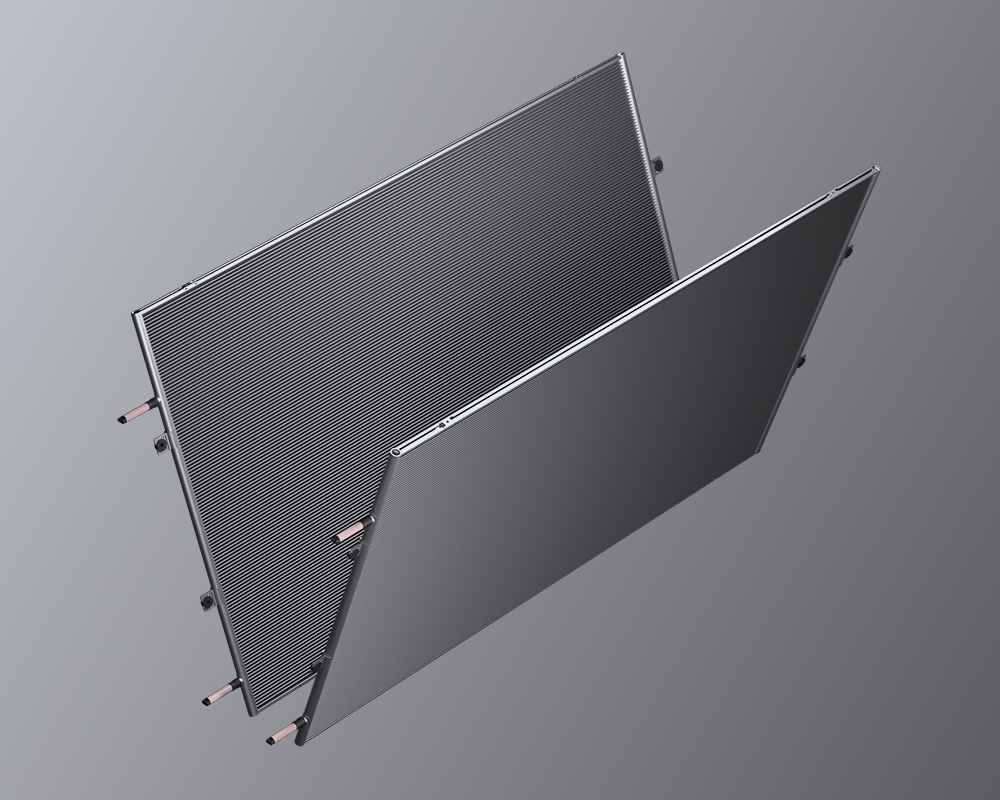

Unbeatable Heat Transfer Rates and High Corrosion Protection

Microchannel technology provides Bora dry coolers with numerous benefits, including higher heat transfer rate, decreased fan power consumption, based on lower airside pressure drops, closer approach temperatures, smaller unit footprint, and reduced weight. The synergy effect is unrivalled performance and efficiency, lower system cost and reduced operating expenses.

High corrosion resistance enables a long lifespan for Bora dry coolers in seashore, aggressive, and chemically polluted atmospheres.

Latest Generation Axial Fans

EFFICIENT, QUIET AND COST-EFFECTIVE FANS

Axial fans used in Bora design have outstanding characteristics in every respect, including performance and efficiency, weight, noise pollutions, and robustness.

EC technology is one of the key foundations of energy efficiency, and Bora dry coolers are equipped with the latest EC motors which demonstrate impressive performance, low energy consumption, high torque, and durable design.

Comprehensive corrosion protection measures have been taken to allow fans to be used in almost all climatic applications with outstanding operating reliability.

PRODUCT SPECIFICATIONS

| Capacity [kW] | 10 … 2000 |

|---|---|

| Fan quantity | 1 … 24 |

| Fan motors | AC/EC |

| Evaporative pre-cooling | AVAILABLE |

| Cooling circuits | SINGLE/DOUBLE |

| Heat exchangers | MCHE |

| Protective coatings | E-COATING/TCP-COATING |

| Refrigerants | WATER/BRINE |

| Warranty | 3 YEARS |